Heat Exchanger Services

NEM Balcke-Dürr´s heat exchanger service covers a wide range of possibilities for repair, maintenance and optimization of heat exchangers. Our capabilities range from inspection to project planning and implementation.

Based on many well proven references we serve the entire range of project execution requirements, including inspection and repair works as wells as manufacturing and assembly.

Engineering capability

- Repair works on site

- Bundle Replacements

- Retubing

- Disassembly and assembly including transport

- Construction site planning

Retubing

Tube exchange of existing heat exchangers under limited time schedule and confined space conditions is our daily business.

We are well equipped with necessary tools for replacement of heat exchangers and condenser tubes. If necessary we will design and construct individual assembly aids.

Even if a high number of tubes or special material combinations make it challenging, we have a proper solution.

- Special equipment for tube removal on stock – available at any time

- Handling of any tube and tubesheet material combination

- Shortest lead times due to individual and customized concepts

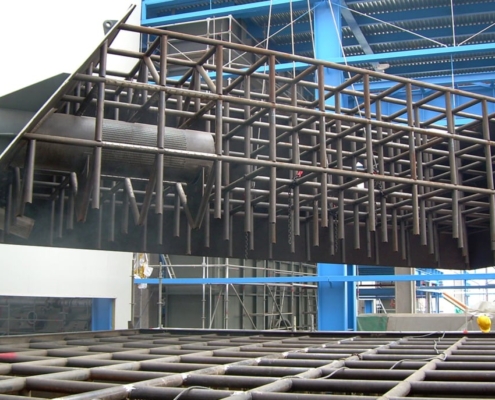

Bundle Replacement

As a specialist for shell and tube type heat exchangers we supply new heat exchanger bundles as an individual solution. Here it does not matter the type of bundle, the type of product nor the application. We are able to serve any type of bundle such as U-type or straight and also Header-type.

We have references for bundle replacements up to largest components ever built. Beside others we replace bundles for condensers, feedwater heaters and district heaters.

- Handling of any tube and tubesheet material combination

- Based on our own engineering we can offer optimizations and upgrades

- Design, manufacturing, disassembly and installation all from a single source

- Special equipment for bundle removal on stock – available at any time

Testing, Cleaning & Plugging

Supported by a broad range of special tools we are able to execute inspections and tests in order to evaluate the condition of entire heat exchangers or only parts of it.

As a provider for complete solutions we also offer an universal service including cleaning and repair, either on site or at one of our workshops.

- Various test methods available such as UT, PT, RT and EC

- Individual tools for cleaning available, e.g. vacuum blast, HP watercleaning (2.800bar), etc.

- Tube plugging with several types of plugs

- Great variety of welding procedures like narrow gap welding allowing repair of largest wall thicknesses

- Own assembly equipment park and manpower enables quick response times

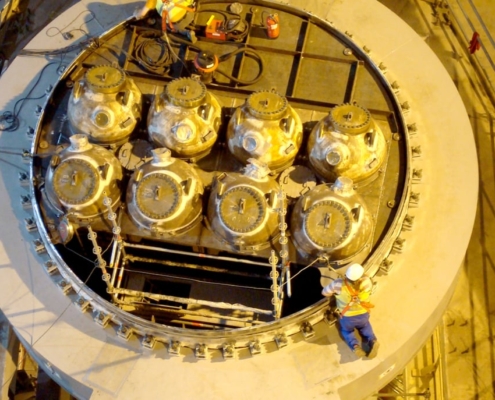

Installation & Disassembly

Based on countless executed projects we will have solutions for most challenging installation situations. Disassembly and assembly of both complete heat exchangers or heat exchanger parts, are one of our core competencies. We serve most difficult tasks by individual solutions and provide consultation under consideration of customer requirements.

- Transport, feasibility and installation studies in 2D- as well as 3D- models

- Special equipment such as chain milling tools available from stock

- Individual lifting beams and chain hoists available from stock

- Air cushion transport systems