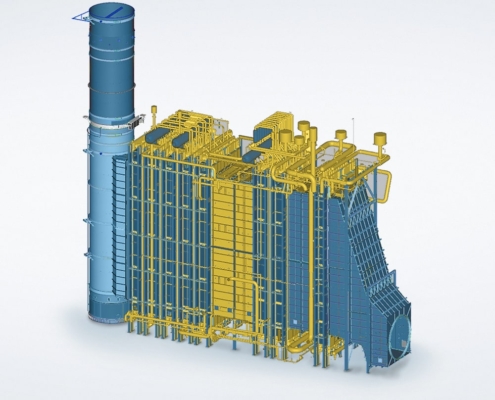

Waste Heat Recovery Units

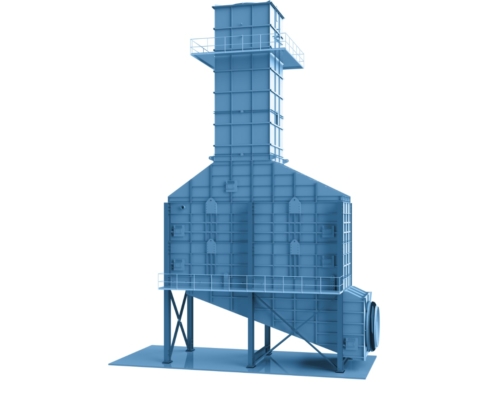

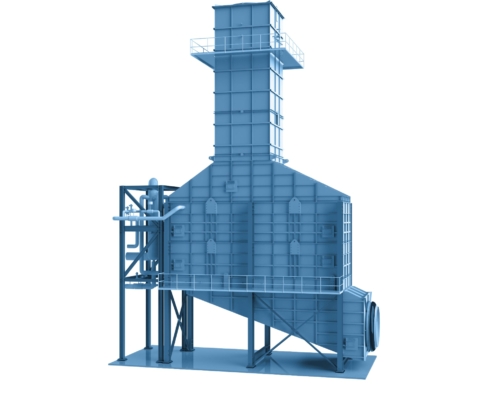

The Waste Heat Recovery Unit (WHRU) range of NEM offers an efficient recovery method of thermal energy from gas turbine exhaust gases, but can also recover waste heat from other heat sources.

The recovered thermal energy can be used for district heating, process heating or for the generation of electrical power via an Organic Ranking Cycle solution. The WHRU can be used for the heating of various Heat Transfer Fluids (HTF’s) like glycol, thermal oil or other Organic fluids. The WHRU can be equipped with duct burners and emissions reduction catalysts. Exhaust gas bypass systems can be installed outside or integral to the WHRU providing operating flexibility and smooth start-up. The system is suitable for both onshore as well as offshore applications.

The WHRU is developed on the same design platform as the Vertical OTSG/DTSG which are used for steam generation and are described below. The vertical gas path design of NEM offers unique modularized construction philosophy resulting in reduced installation time and costs. This modular philosophy applies to our entire design platform in this range.

Products

- NEM WHRU

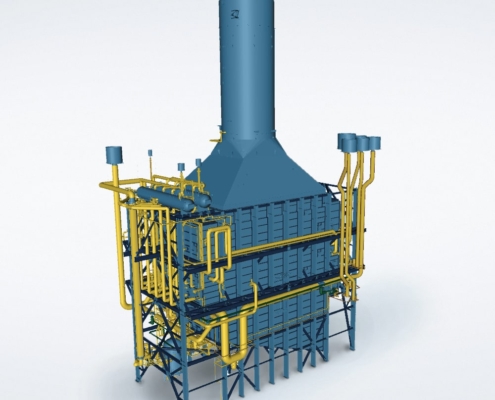

Modular Heat Recovery Steam Generators

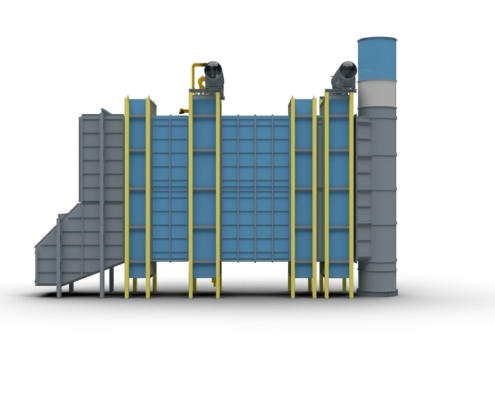

In the range up to 75 MW gas turbine output, NEM offers the best of both worlds. A modularized vertical as well as a horizontal design.

The vertical Once Through Steam Generator (OTSG) is perfectly suited for fast start and cycling operations. The vertical Drum Type Steam Generator (DTSG) offers the benefits of a vertical design such as a small plot space requirement as well as the benefits of a modular construction approach. The Horizontal Drum Steam Generator of modular design allows for a great deal of customization and is typically used in more complex co-generation applications with a high degree of supplementary firing.

NEM modular HRSGs can be used in a variety of industries and are suited for both onshore as well as for offshore applications. NEM has dozens of references around the globe with the modular construction approach which has proven to be the best choice for the lowest total installed costs.

Products

- NEM DTSG

- NEM OTSG

- NEM HDSG

Large Heat Recovery Steam Generators

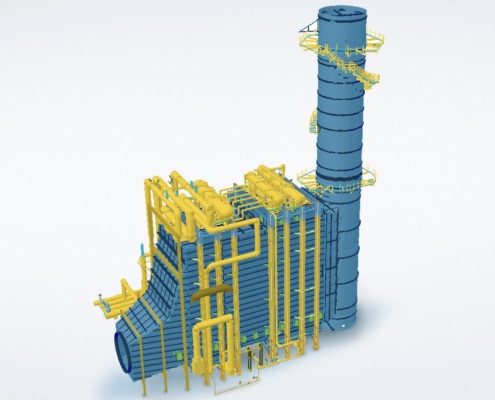

With hundreds of units installed in the world, NEM is one of the key players when it comes to developing HRSGs for the largest gas turbines on the market.

NEM has already installed dozens of HRSGs behind H- and J- class gas turbines, many are already in successful commercial operation while others are currently under construction. New HRSG innovations has come from NEM over the past decades that allows units to be more flexible in operation as well as quicker installed.

In addition, changing electricity markets and the use of more renewable sources on the grid, impact the operating regime of Combined Cycle Power Plants and also HRSGs. NEM offers unique fast start and cycling design. NEM’s patented DrumPlus™ design (NEM HNC+) has been developed into a 2.0 version with both the benefits of operational flexibility as well as smoother installation on site. Also when such operations is not foreseen in the first years, it is recommended to install such as design in order to be prepared for the future. NEM also offers the vertical Once-Through design (NEM VOT), licensed by Siemens Energy.

Also in the area of large HRSGs, offering both the vertical as well as the horizontal gas path design, allows for the best fit for the project. Our NEM VNC concept is for instance suited for gas turbines that are operating on heavy fuel oil, where the horizontal concepts are better suited for projects with a high degree of supplementary firing. All in all, NEM has a fit to purpose HRSG portfolio that is build on almost a century of experience in delivering quality.

Products

- NEM VNC

- NEM HNC

- NEM HNC+

- NEM HOT

- NEM VOT