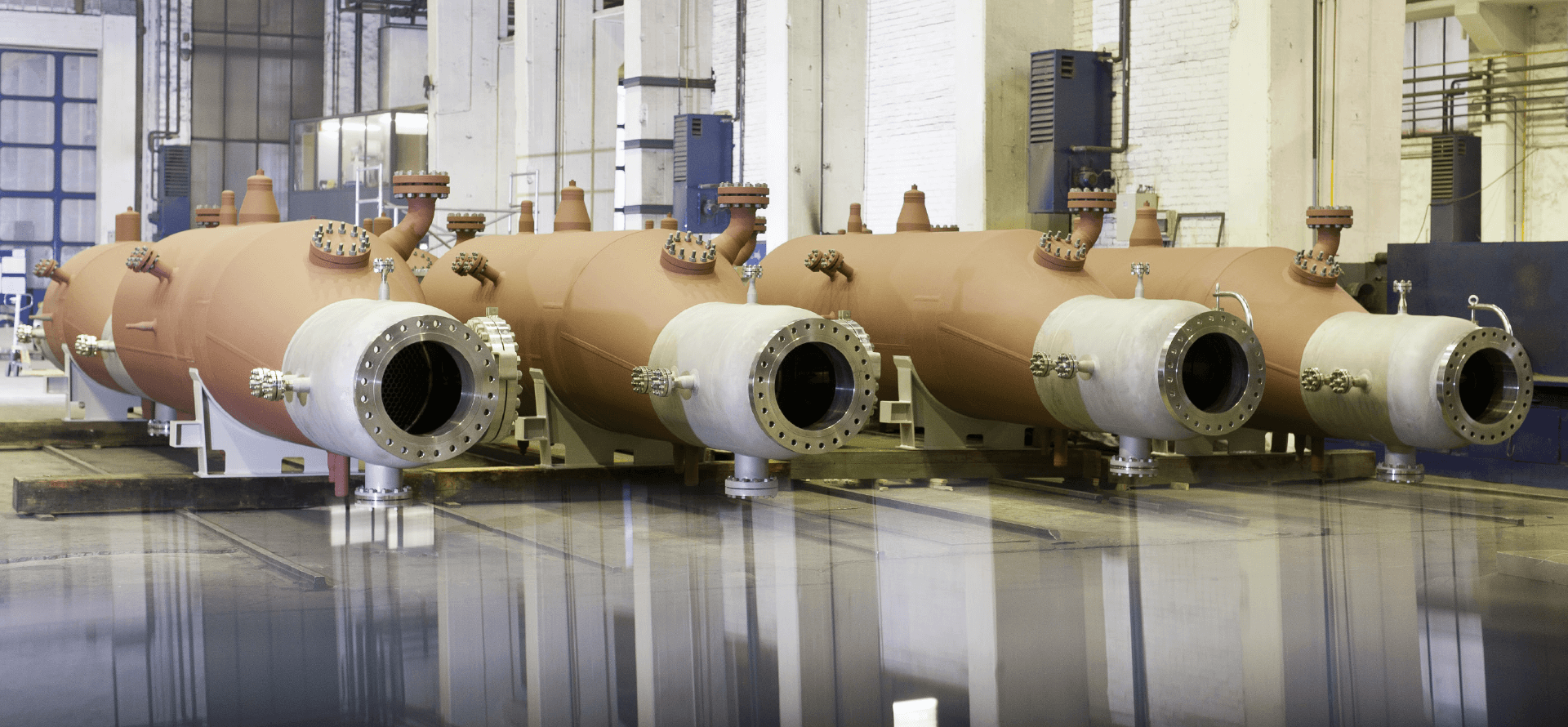

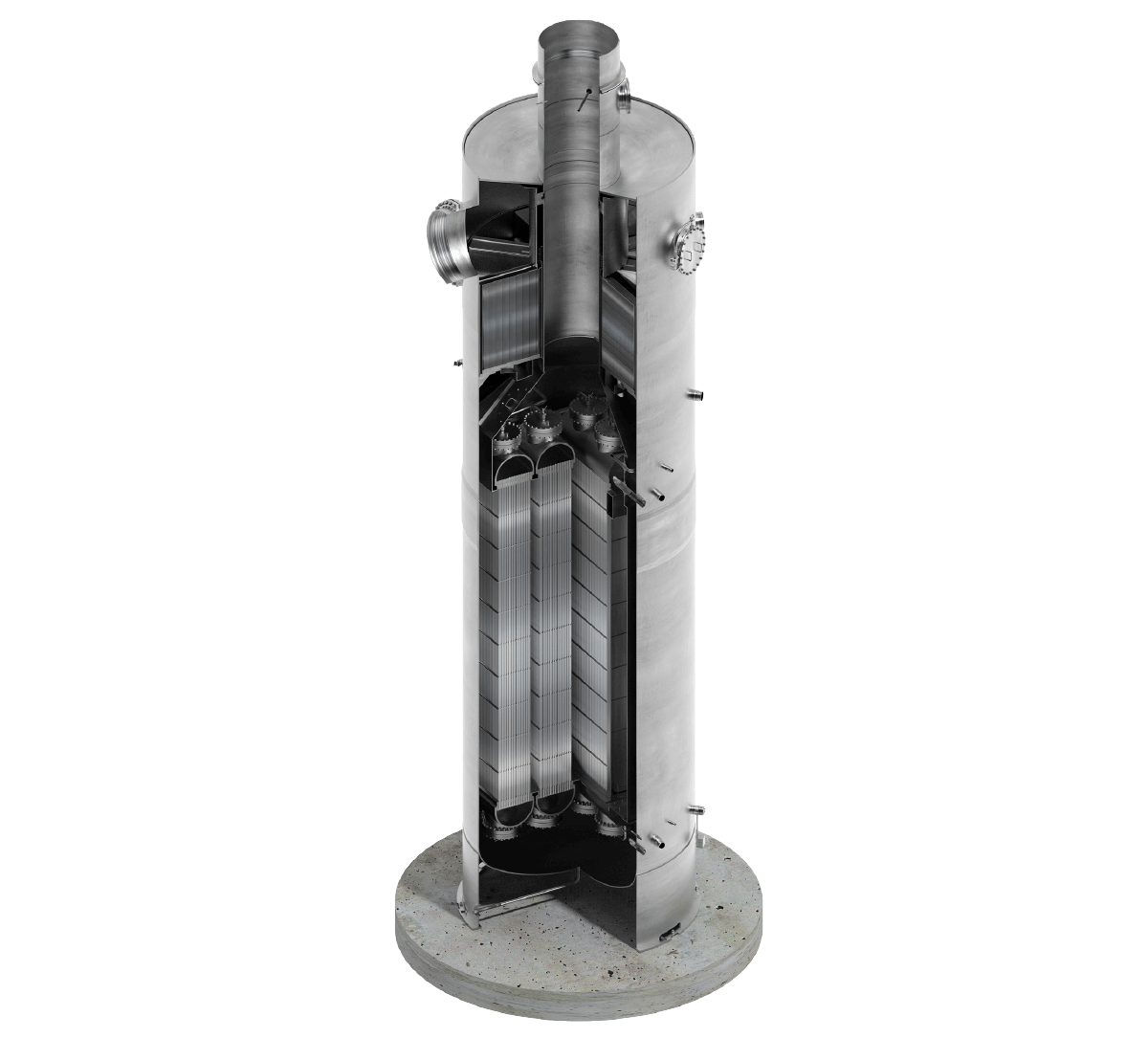

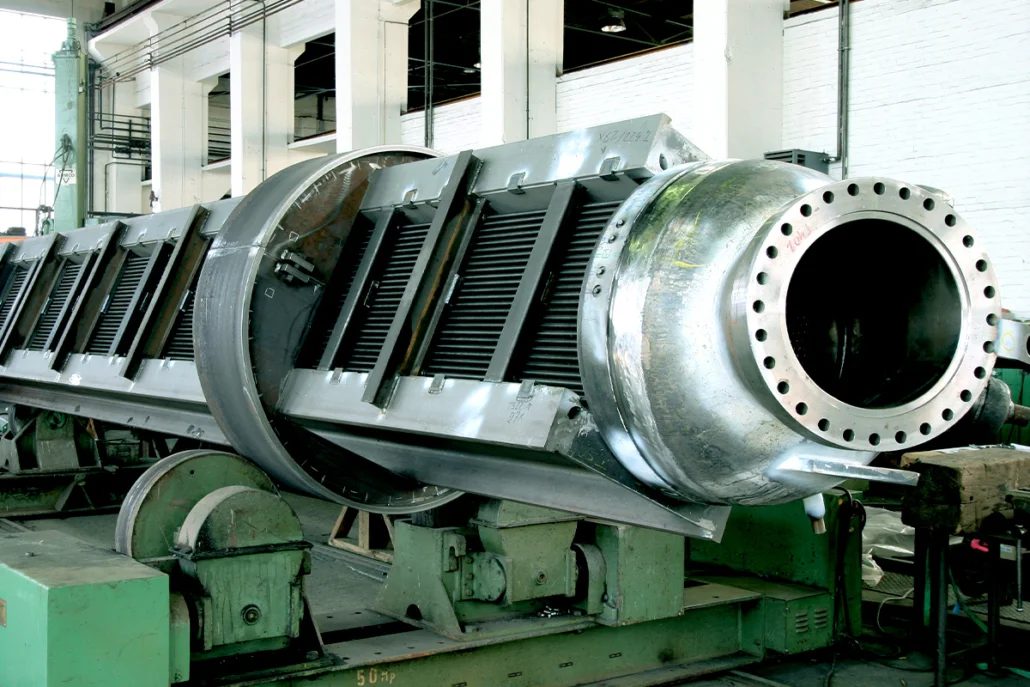

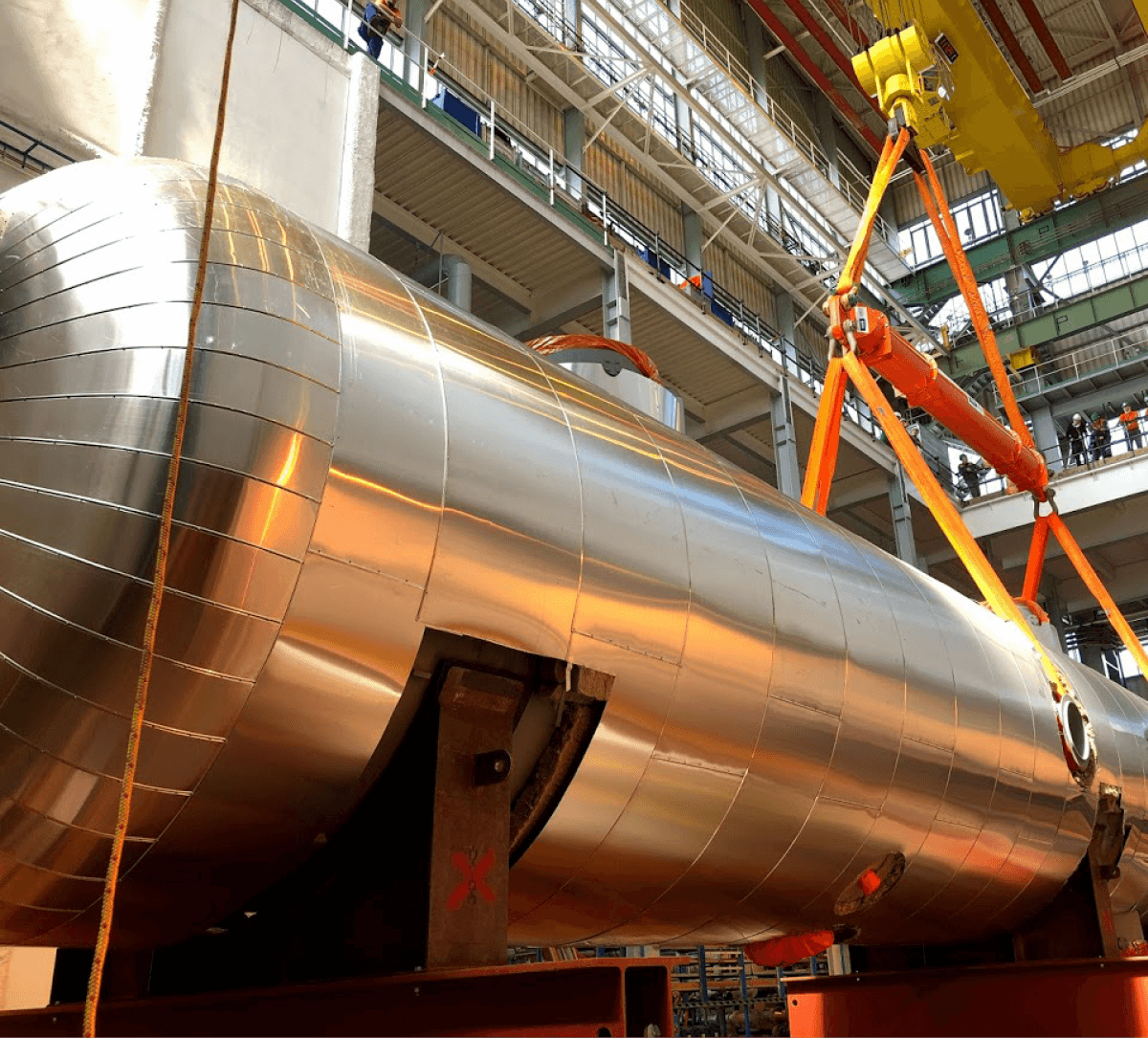

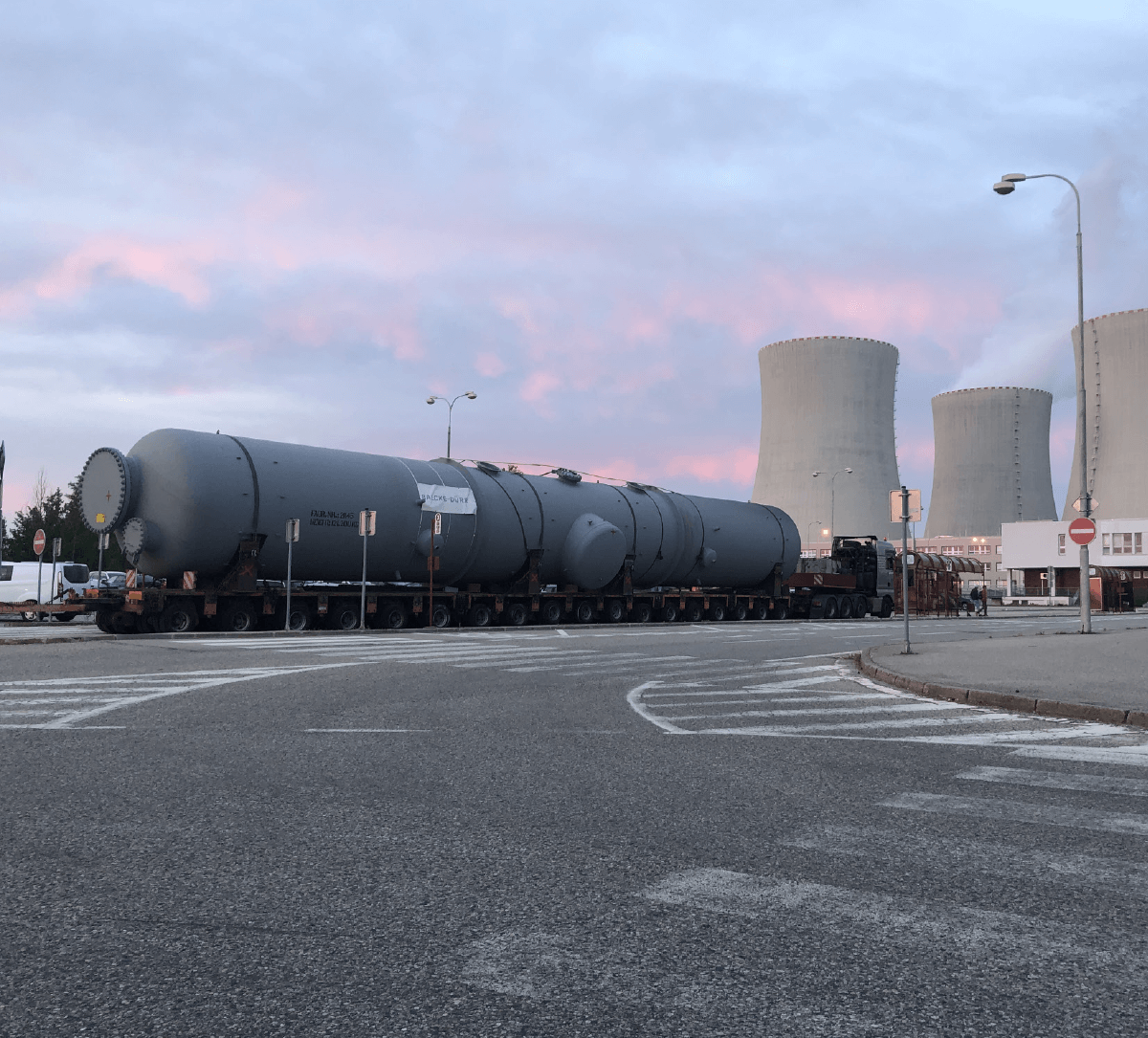

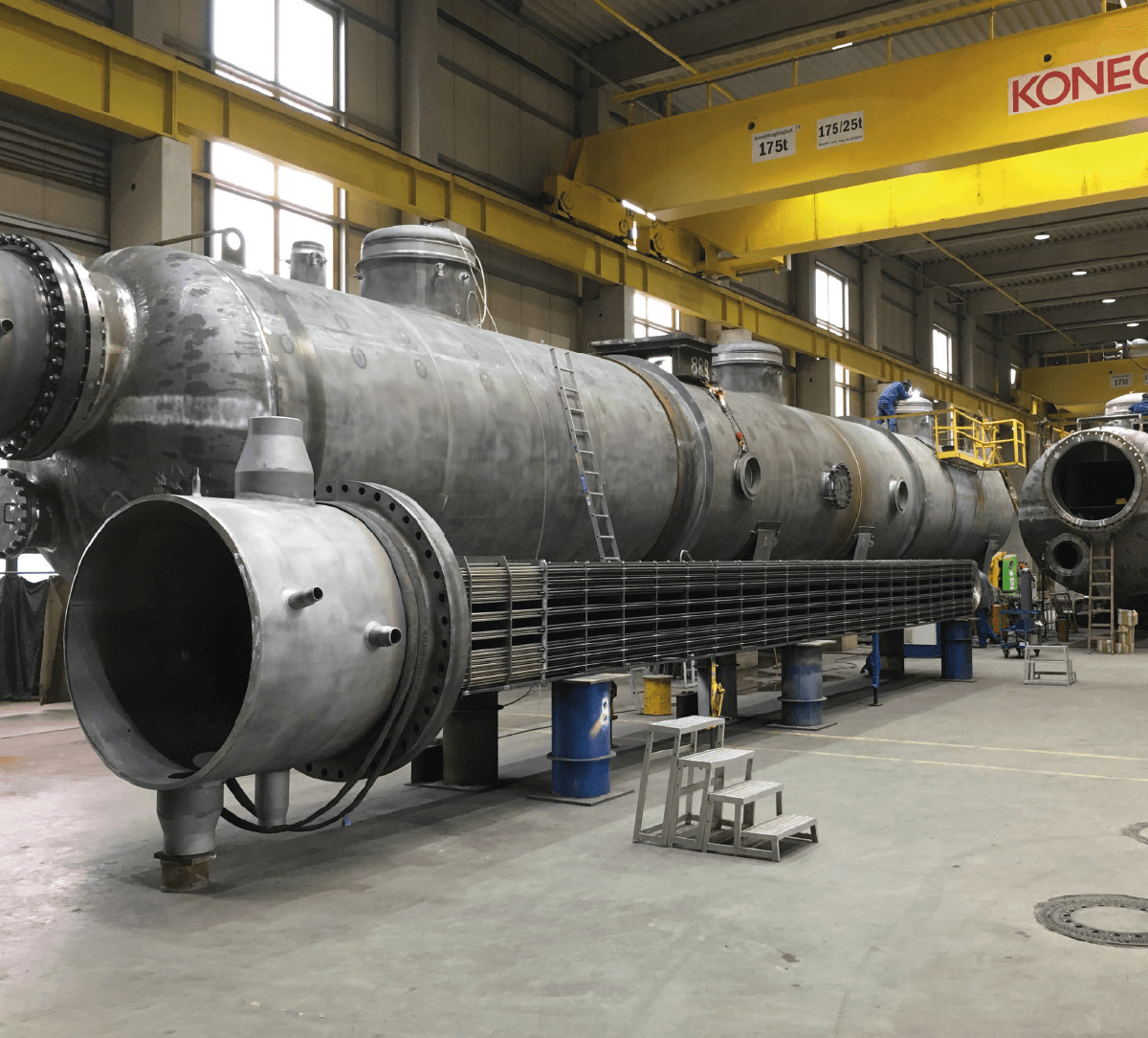

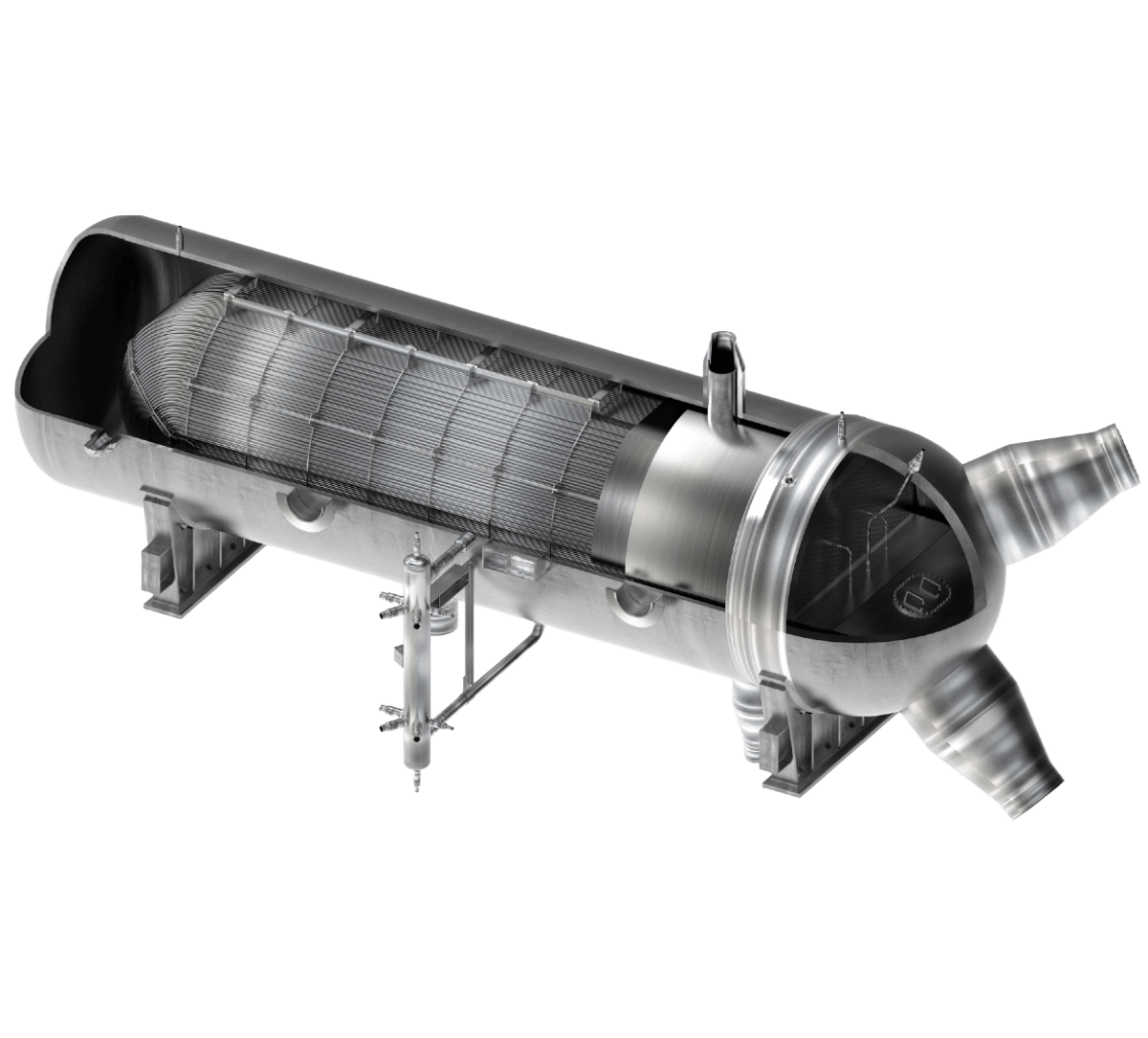

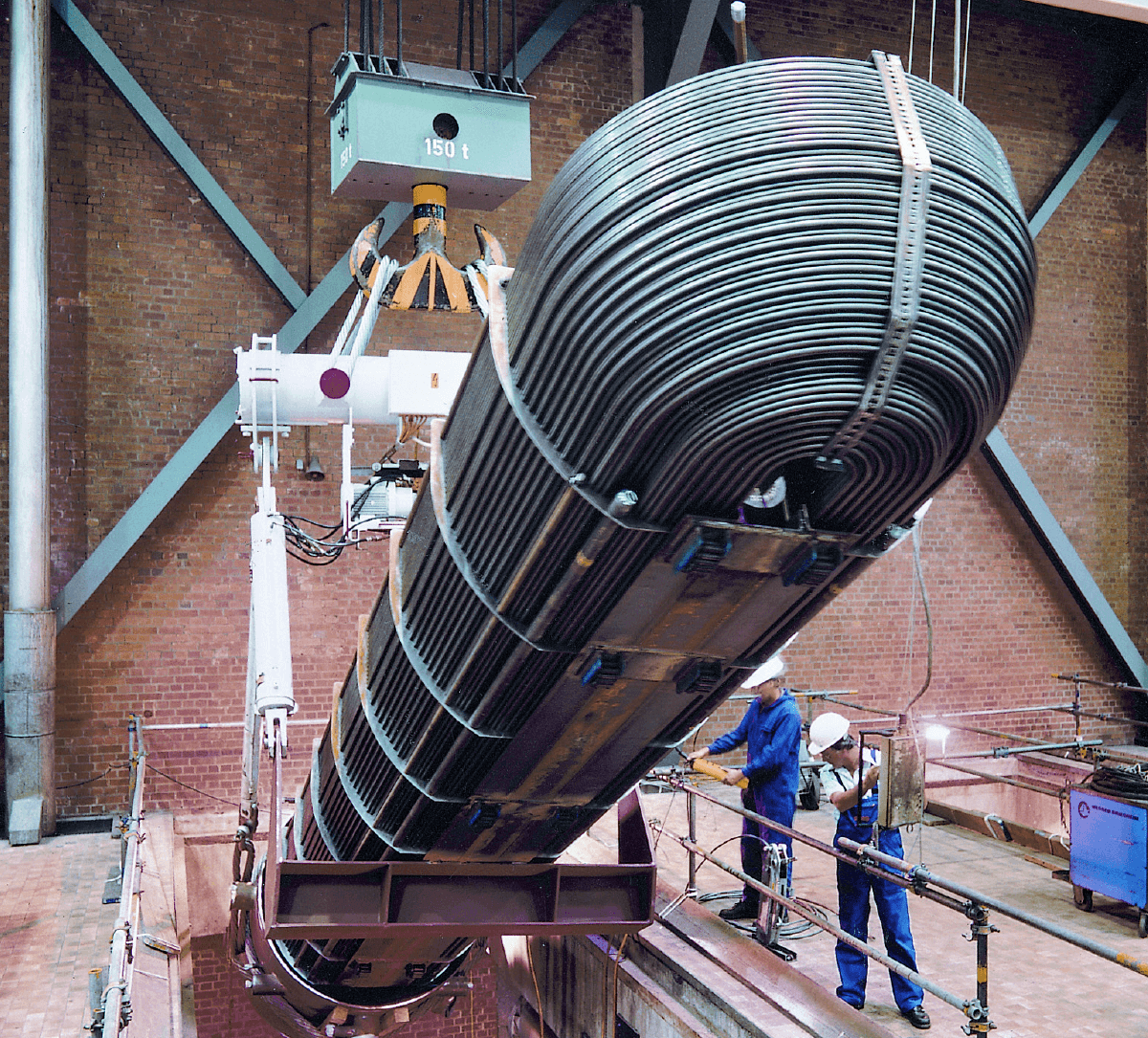

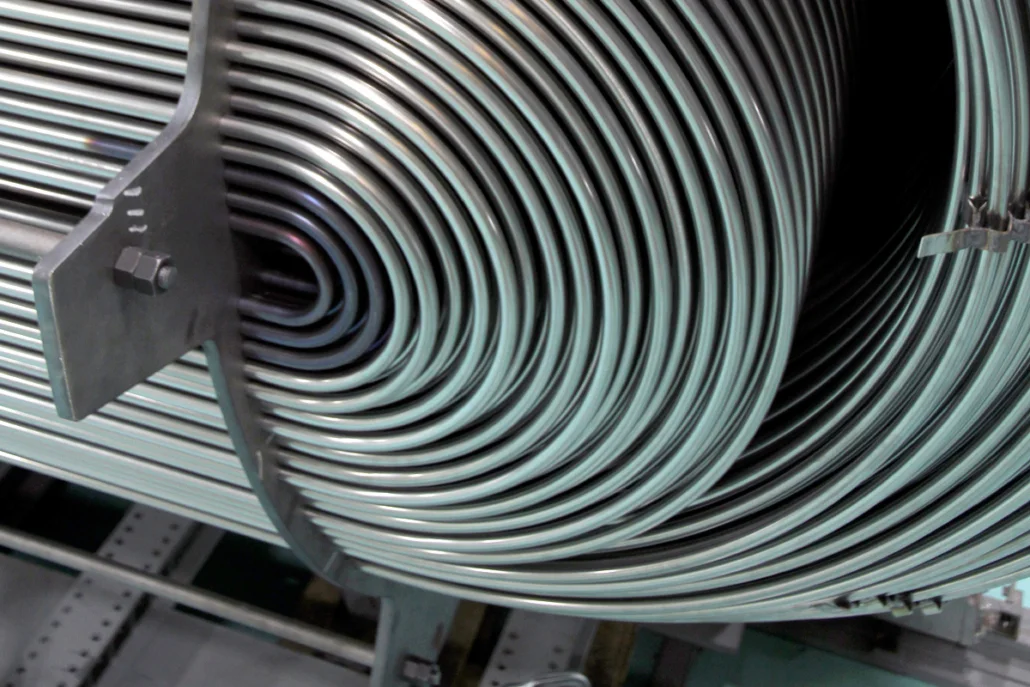

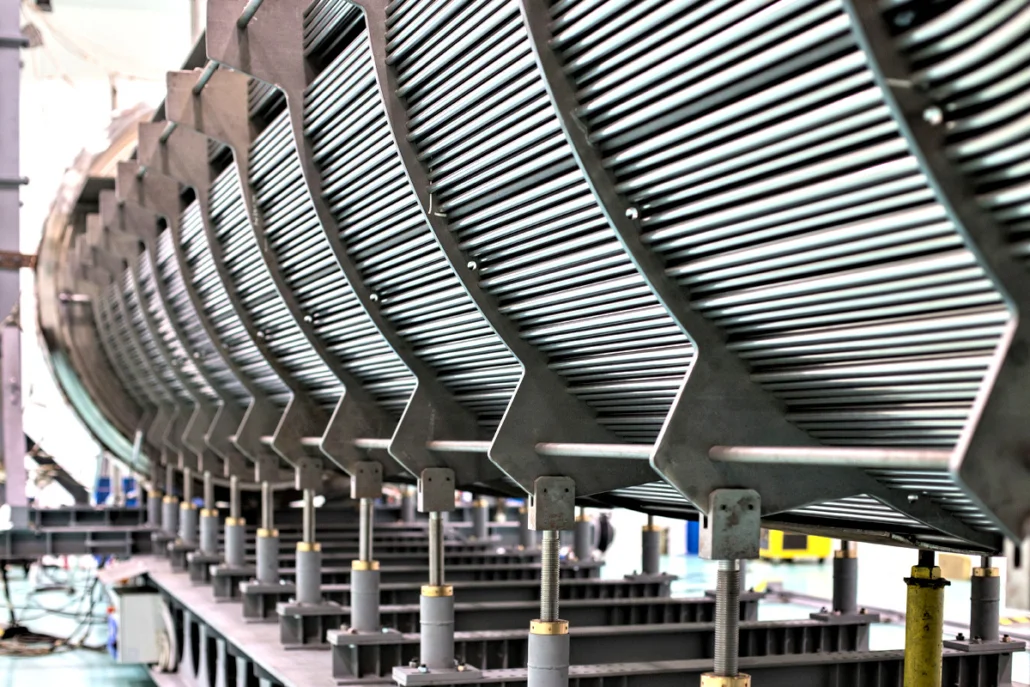

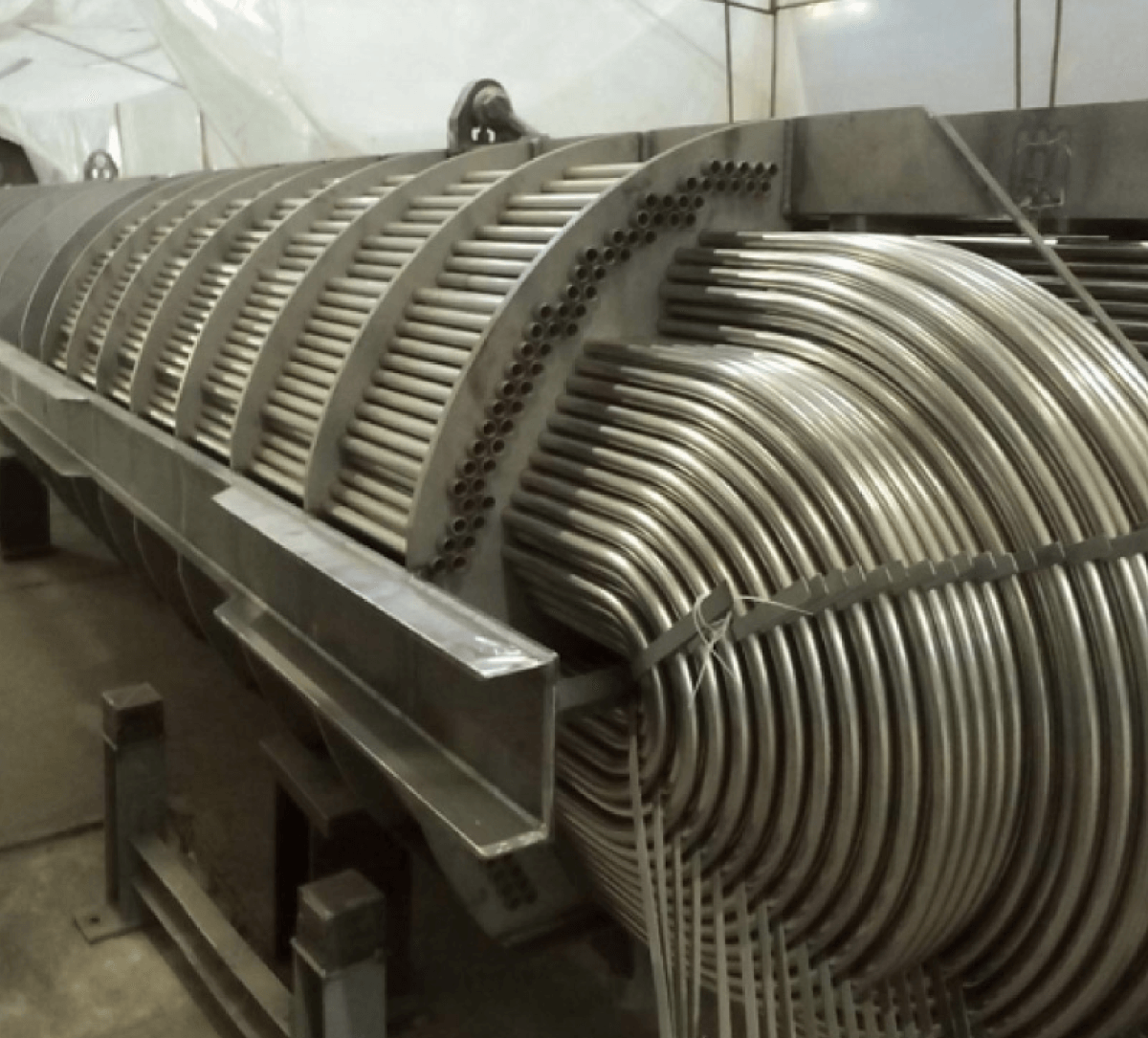

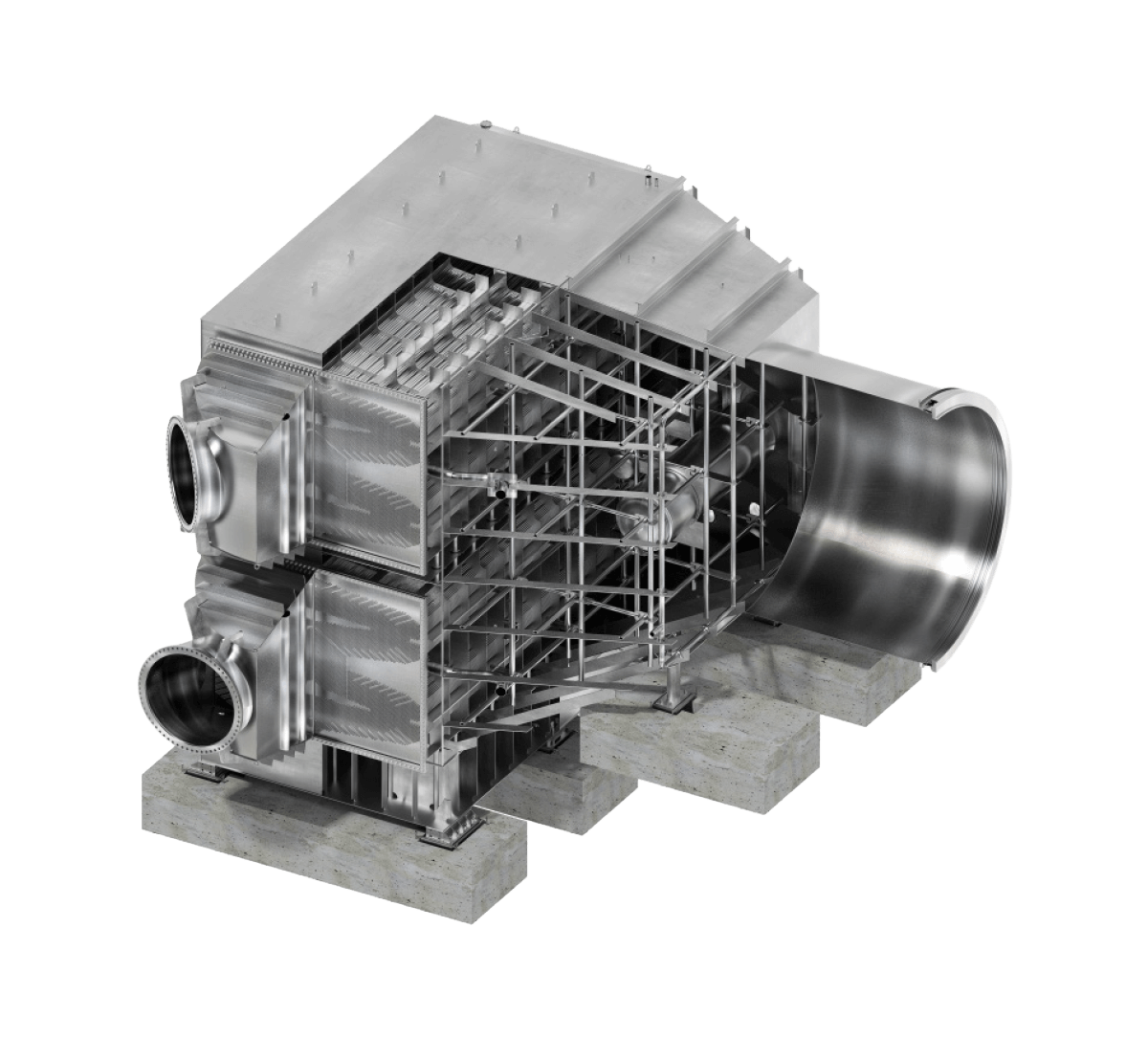

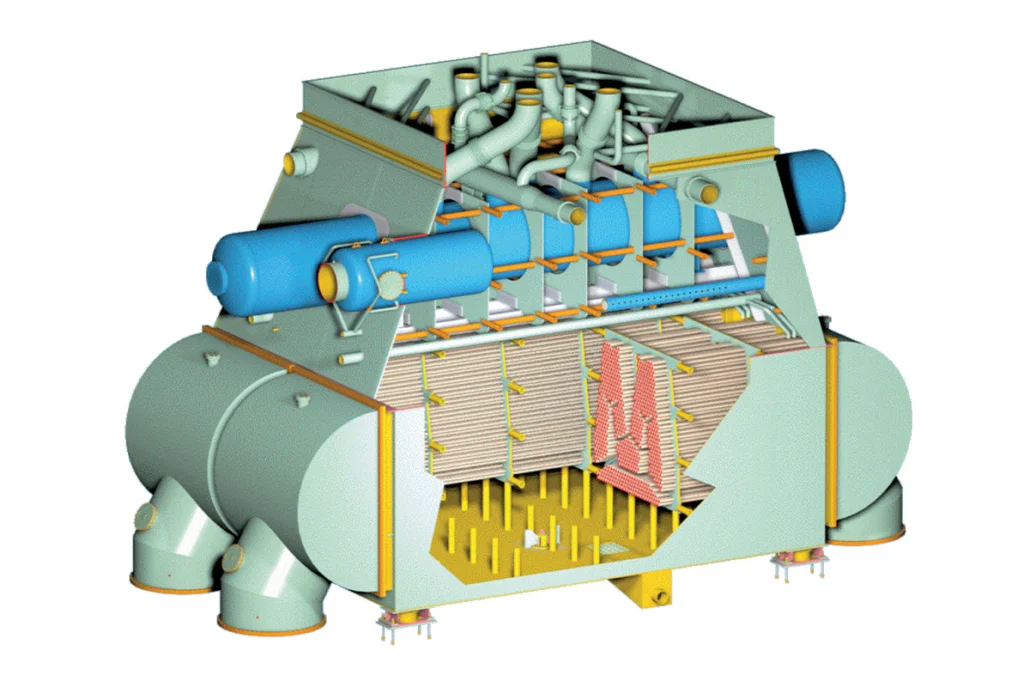

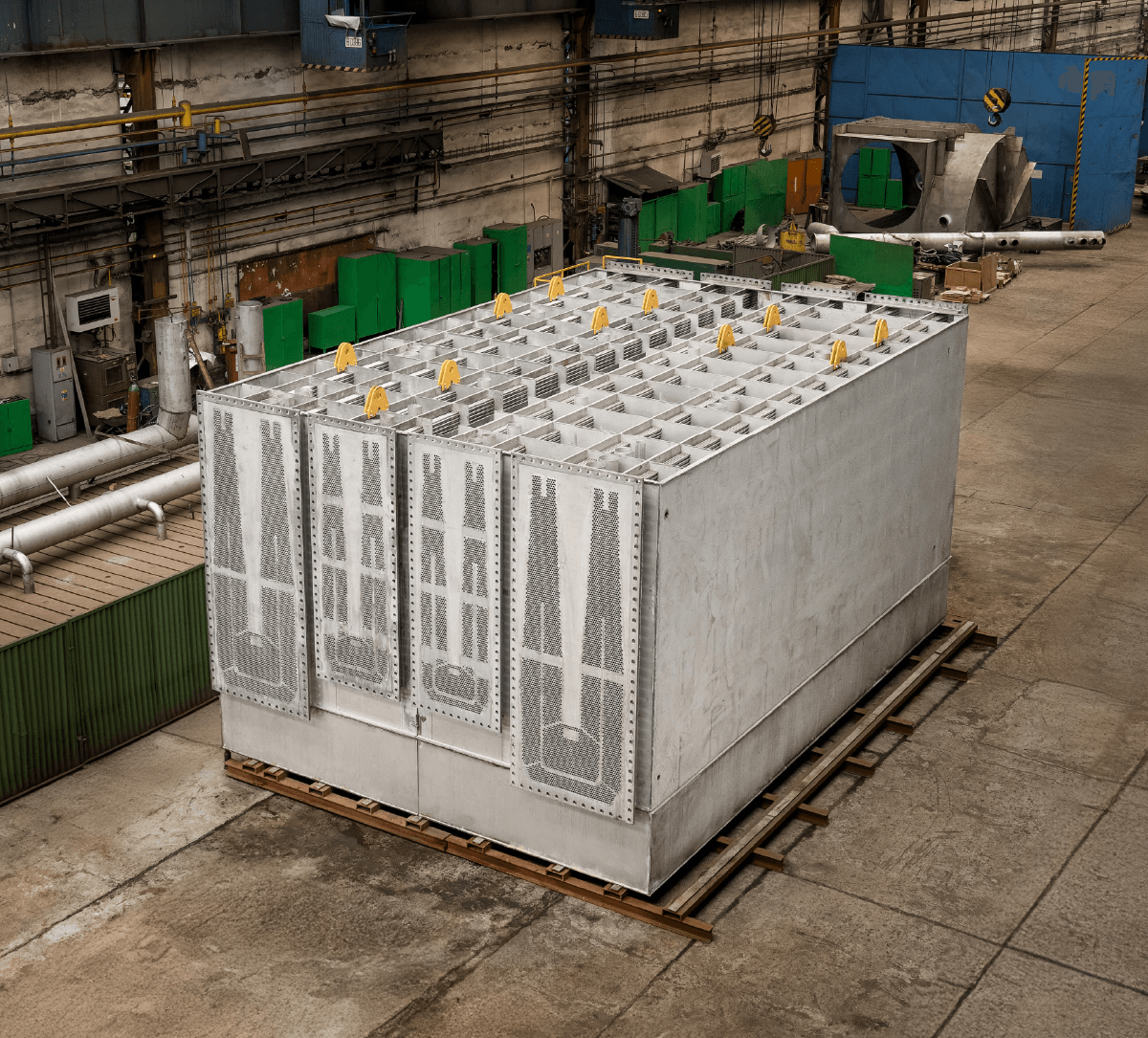

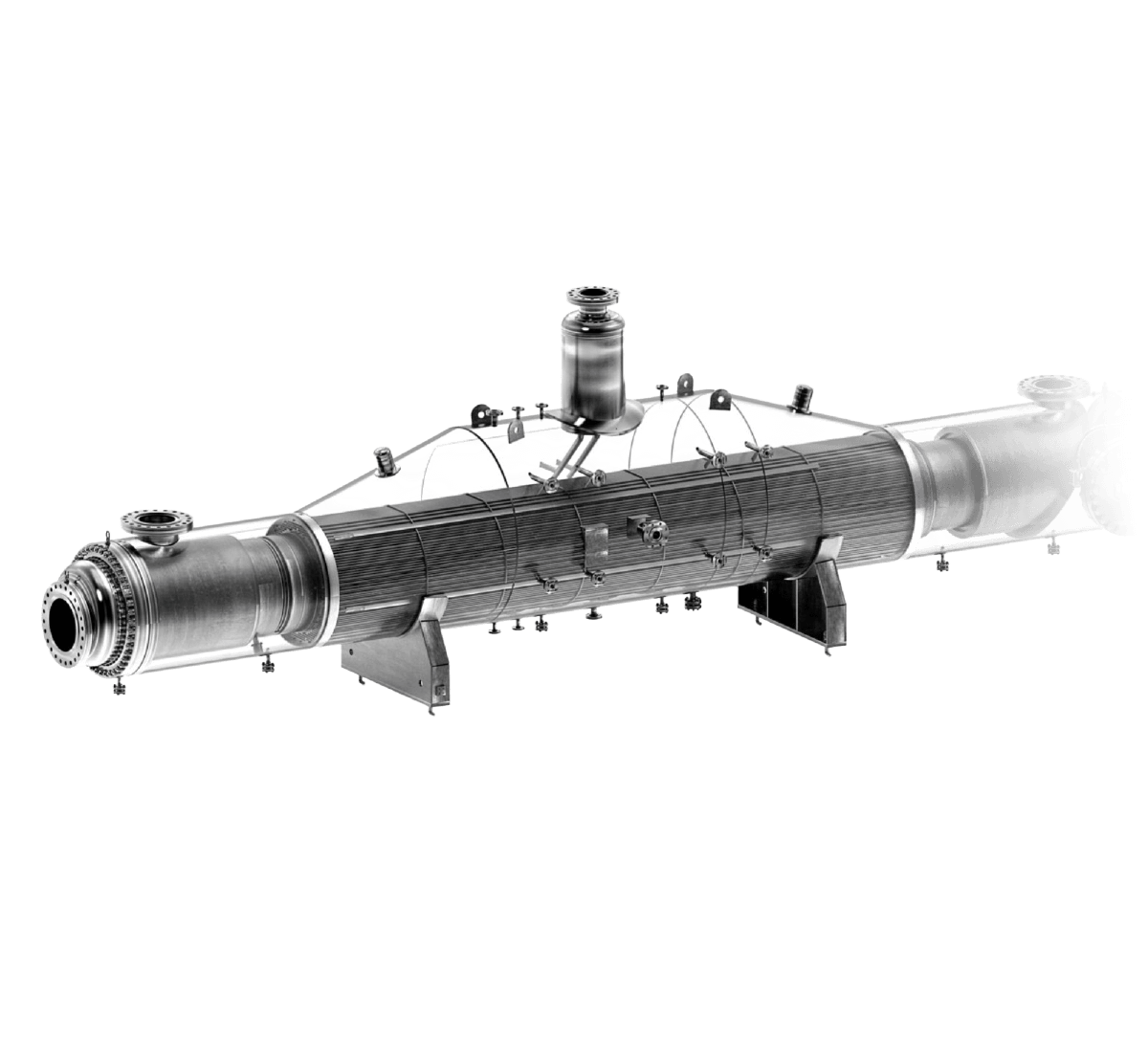

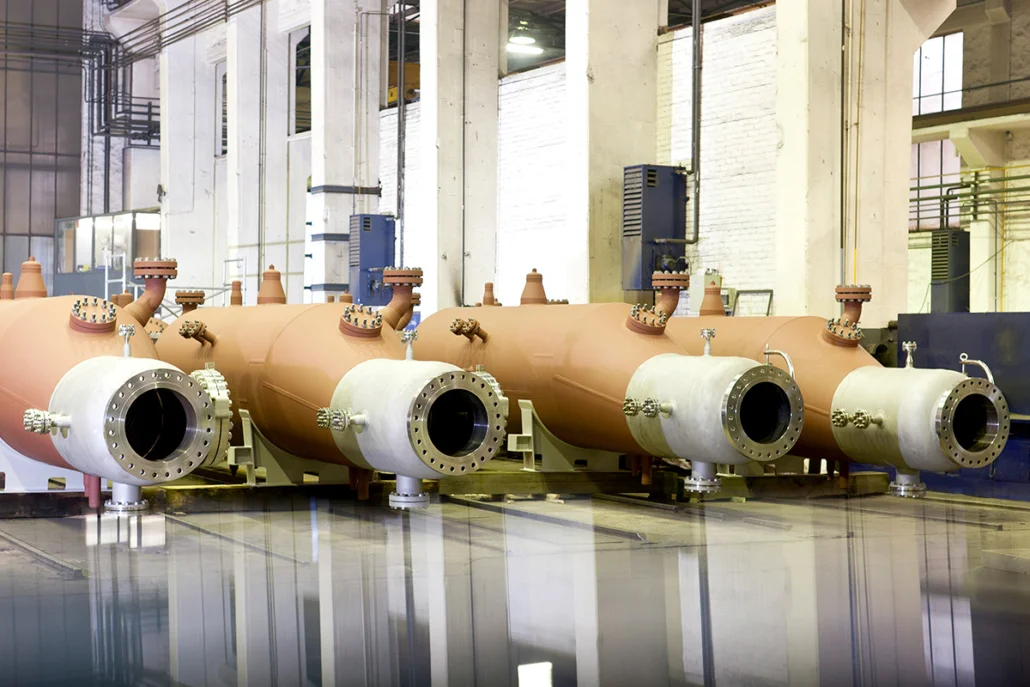

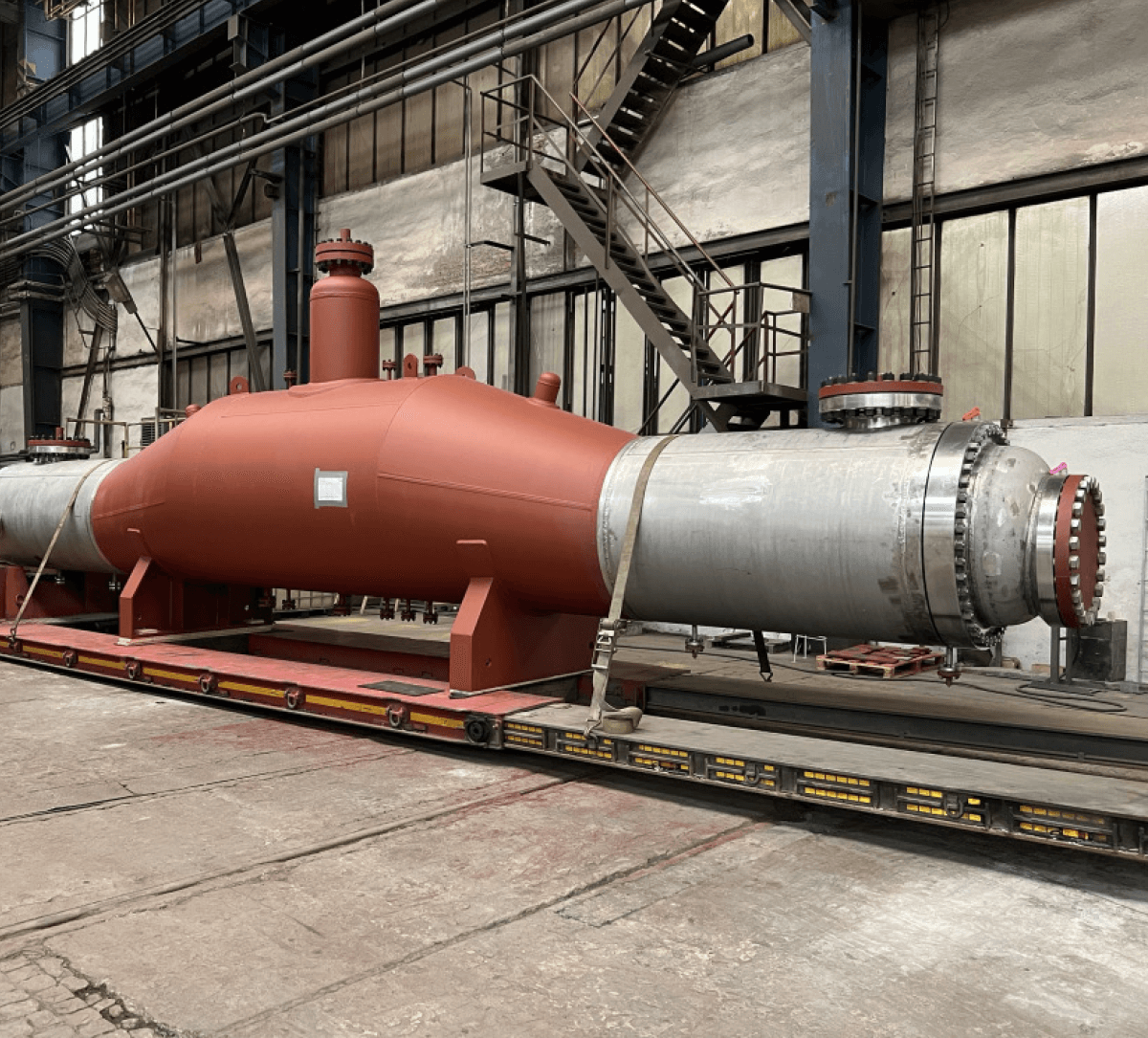

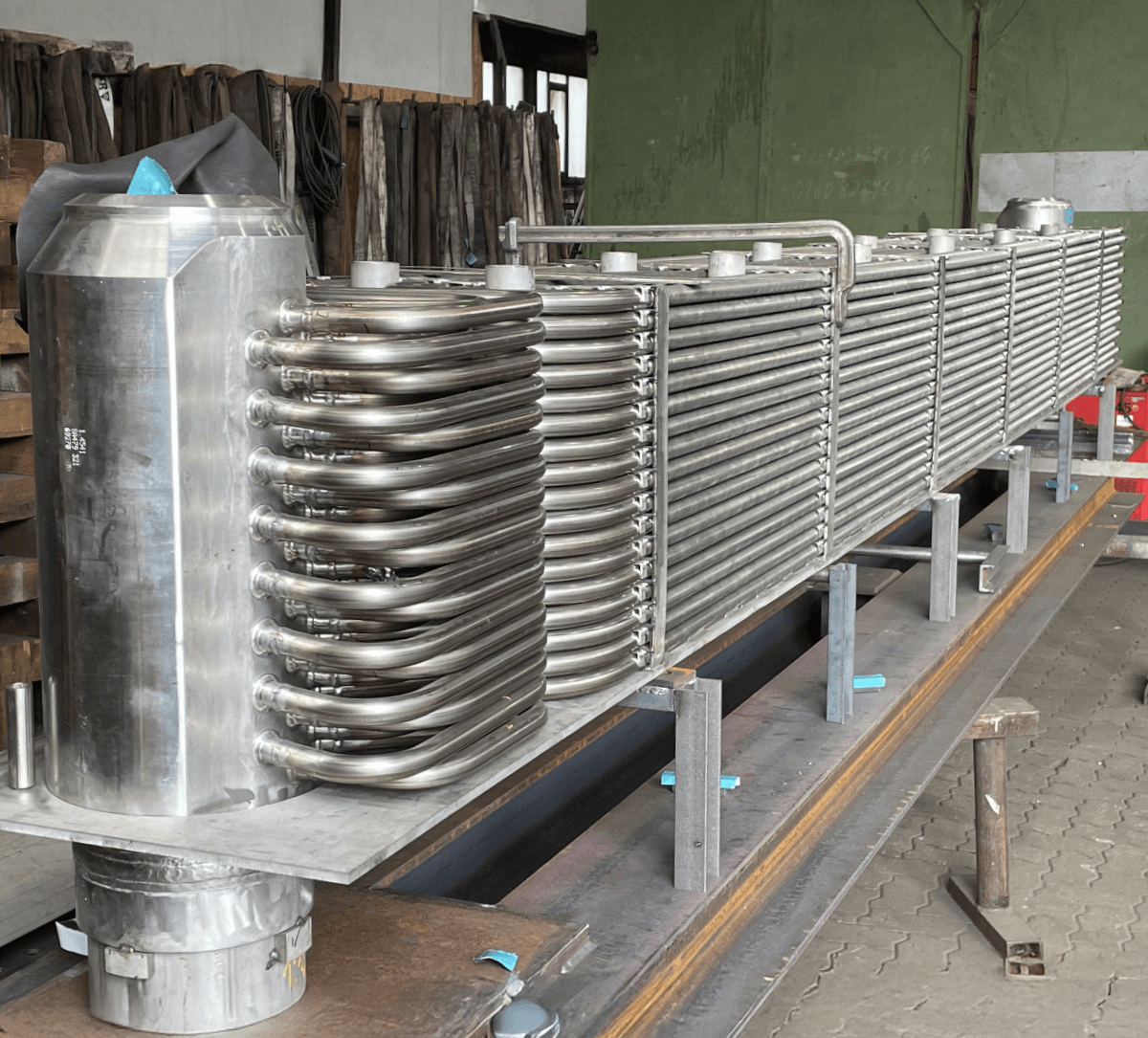

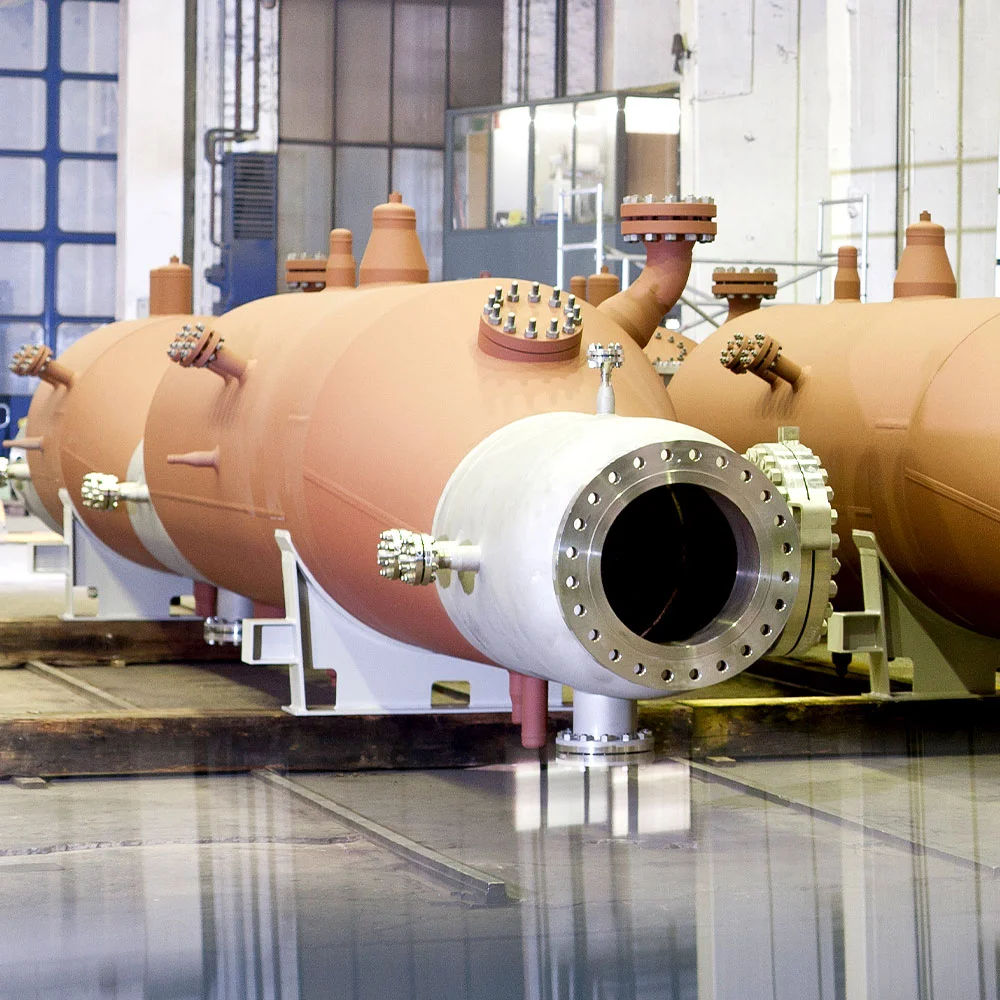

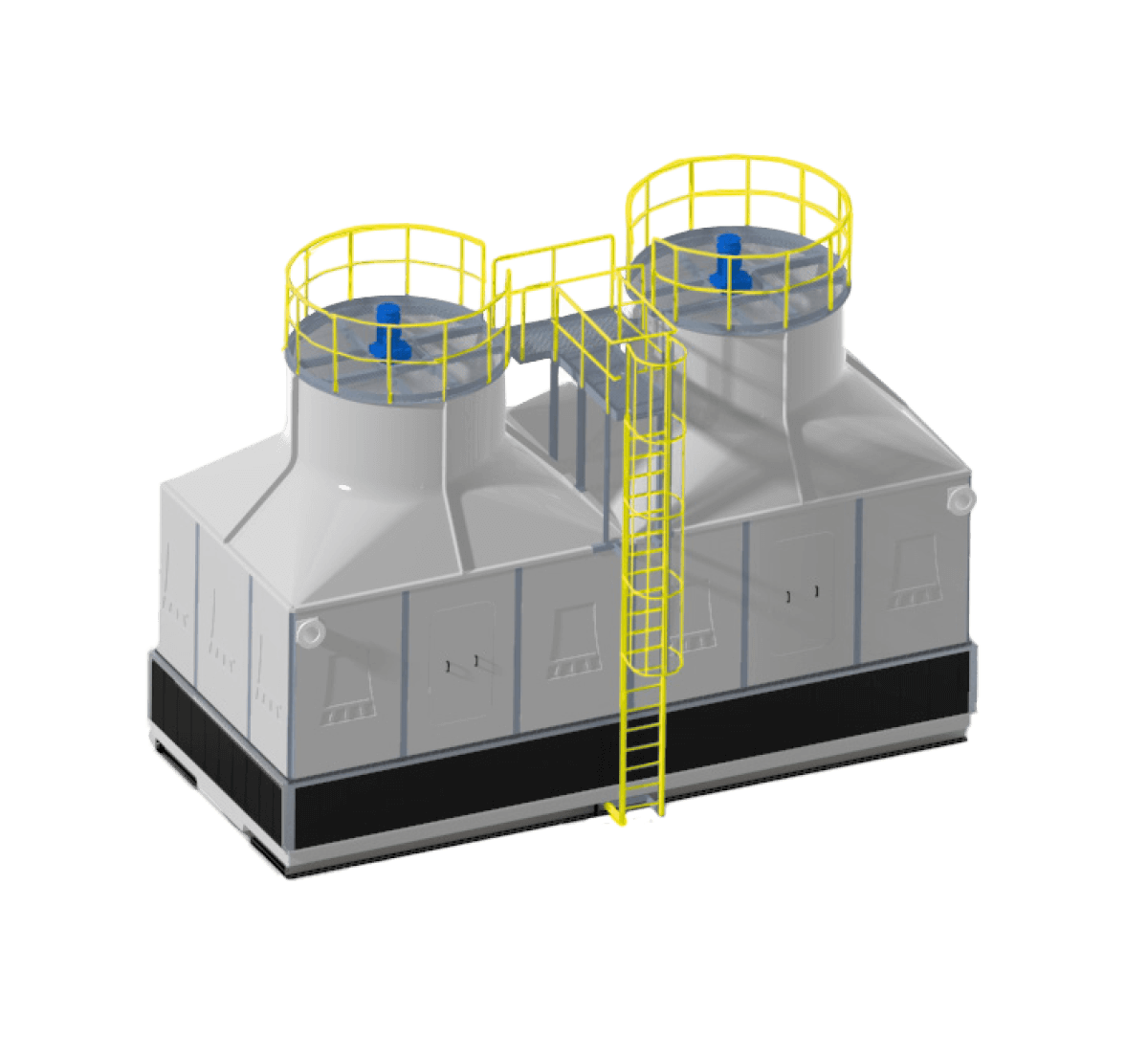

NEM Energy Group, together with the extensive knowledge and expertise of NEM Balcke-Dürr—active since 1883 as an Original Equipment Manufacturer (OEM) in the field of heat exchangers, offers a wide range of products for various applications, including nuclear, geothermal, and gas-fired power plants. Drawing on the long-standing experience of NEM Balcke-Dürr, we have contributed to numerous significant industrial developments over the years. Our comprehensive portfolio includes a broad selection of heat exchangers and reactors, enabling us to deliver reliable, customized solutions that meet the specific needs of power, chemical, and industrial facilities worldwide. The portfolio of heat exchangers focuses on four product ranges, explained further below.

Heat Exchangers