We provide energy solutions for both existing and emerging markets in the energy transition. NEM’s products are used across a wide range of applications and industries. We offer competitive solutions that support flexible, efficient power and heat generation for all types of industries.

-

Power & Heat Generation

-

Oil & Gas

-

Industries

-

Renewables & Hydrogen

-

Energy Storage

-

Nuclear

-

Geothermal

-

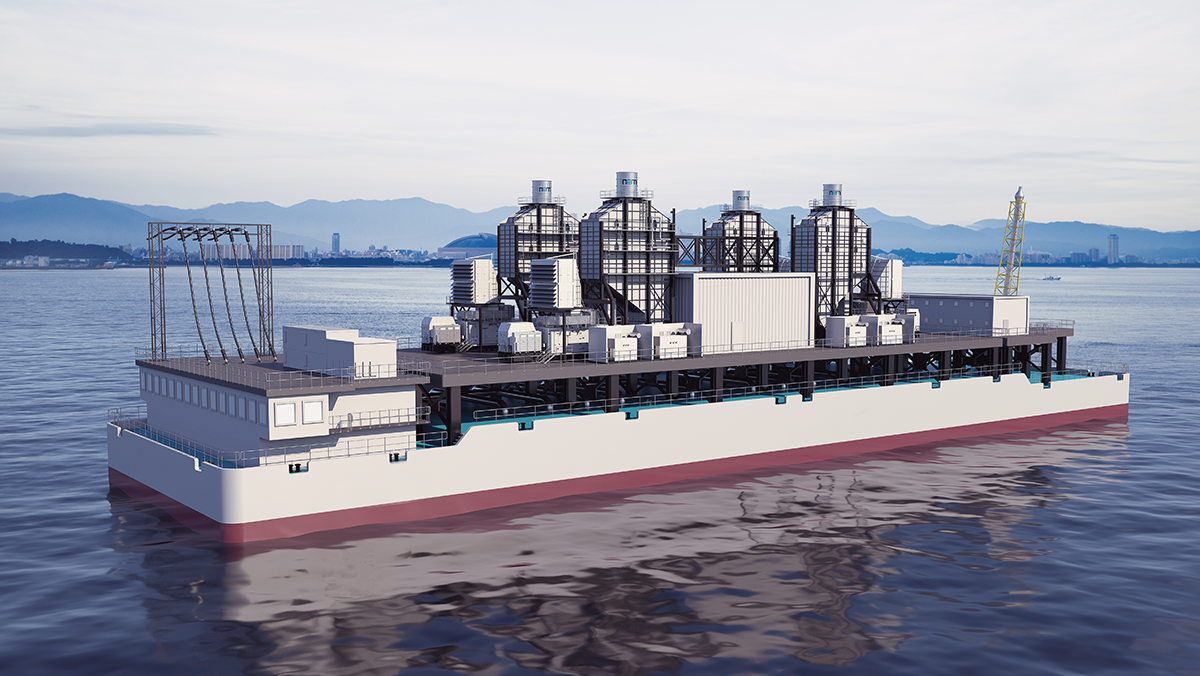

Offshore Power Generation

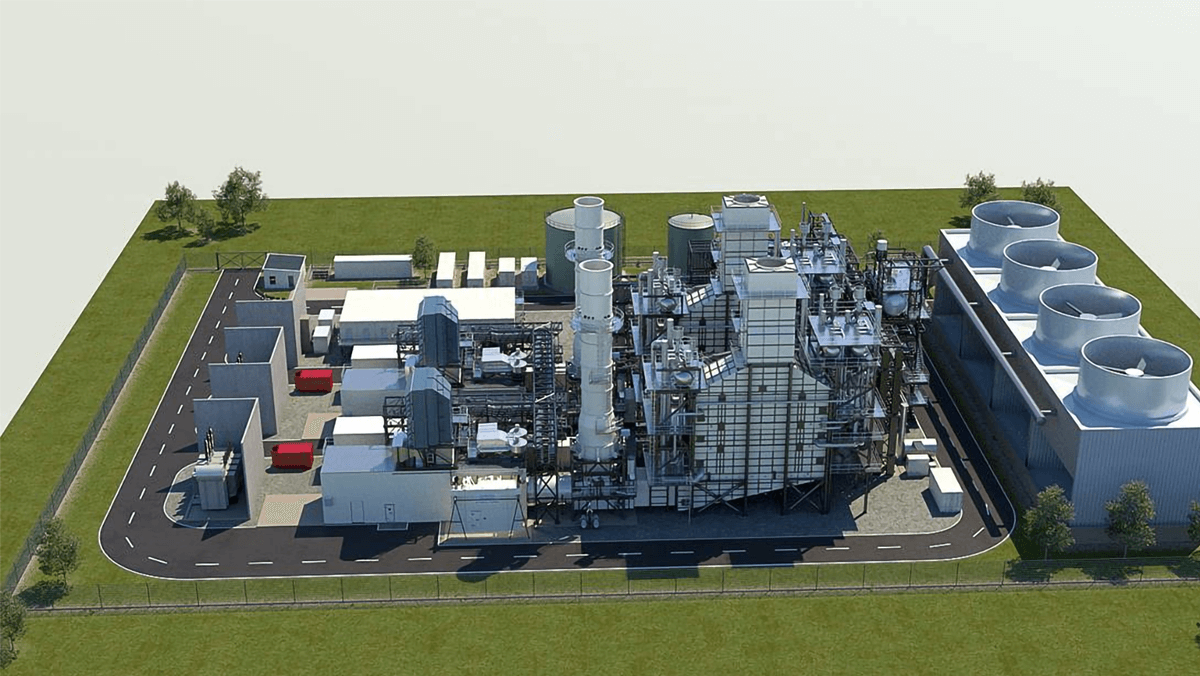

Power & Heat Generation

Whether for gas turbine combined cycle power plants (CCPP) or combined heat and power (CHP) plants, NEM offers competitive solutions to support new, flexible, and efficient power generation. The global power markets are changing faster than ever before. The complexity of the energy system demands that new power plant solutions become more flexible, while also requiring a high level of efficiency.

The need for more flexibility has everything to do with an increasing amount of renewable energy connected to the grid. Power plants need to become more flexible, ramping up faster and dealing with a challenging operating regime in order to be able to cope with fluctuating renewables.

NEM offers a unique variety of product designs taking into account these market requirements, preparing customers for different plant operation scenarios in the future. Gas turbine power plants are becoming more efficient in converting the chemical energy in the fuel, often natural gas, into electrical energy supplied to the grid. The steam cycle in a gas turbine-based power plant is increasingly important as the waste energy of a gas turbine needs to be converted into electricity in the most efficient possible way. NEM thermal design capabilities are second to none and allow for optimal heat transfer in a combined cycle power plant, leading to the highest efficiencies.

Combined Cycle Power Plants (CCPP)

NEM Energy supplies a range of equipment for Combined Cycle Power Plants (CCPPs), supporting both the gas and steam cycles.

Rotor Air Cooler: Solves the stress corrosion problem faced by many gas turbine applications. The innovative, patent-pending design is based on stress corrosion-resistant material, the elimination of the expansion joint, and heat protection of critical parts. This protects the cooler against excessive fatigue from thermal cycling and increases its availability.

Exhaust Gas Bypass Systems: These systems contribute operational flexibility, maintainability, and safety to a combined cycle power plant.

Condenser & Cold End Solutions: Heat Recovery Steam Generator (HRSG) captures exhaust heat from the gas turbine and uses it to produce steam. This steam can then be used for power generation or industrial processes. The Condenser returns the used steam to water, enabling it to be reused in the cycle.

Check out our products and aftermarket services in this market

Oil & Gas

In order the reduce the amount of CO2 emitted per barrel of oil or gas produced, companies are taking actions to increase efficiency and reduce their carbon emissions.

NEM offers a unique set of products, whether for onshore or offshore heat recovery. For instance, onshore NEM is providing heat recovery solutions for gas turbines in mechanical drive applications. Often these gas turbines run in open cycle, but recovering waste heat can drastically improve the efficiency of the overall plant. The waste heat can be used to heat up any other type of gas or liquid. For offshore applications, NEM has a unique and patented ‘Ultra-Light’ design.

Here, the installation is designed as such to reduce weight to the optimal extent. This results in the lowest total installed costs for our customers and allows customers in offshore areas to increase their gas turbine plant efficiency immensely. This so-called Ultra-Light design can be supplied for new gas turbine facilities for FPSO, FLNG, or fixed rigs, as well as to convert an existing offshore open-cycle gas turbine to a combined cycle.

Check out our products and aftermarket services in this market:

Industries

Energy intensive industries often generate their own energy. Pulp and paper is a good example of such an industry. The production process requires heat, and heat is often supplied as steam in the plant. Various pulp and paper companies combine the production of electricity with the production of heat for their production process.

NEM offers water/steam-based heat recovery solutions as well as other types of heat recovery cycles, such as for an Organic Rankine Cycle (ORC). Here, waste heat is recovered using an organic heat transfer medium. The organic heat transfer medium is then routed to an ORC turbine rather than a steam turbine for the generation of electricity.

Especially, the combination of power and heat production can be done very efficiently using a cogeneration process. Here, a gas turbine and heat recovery steam generator are coupled to generate both electricity through the gas turbine and generator, while producing heat using the gas turbine’s waste heat as an energy source. In case more steam is needed for the process, the heat recovery steam generator can also be equipped with a supplementary firing system to fit the plant’s requirements. Also, in other industries, heat and heat recovery play an important role.

Check out our products and aftermarket services in this market:

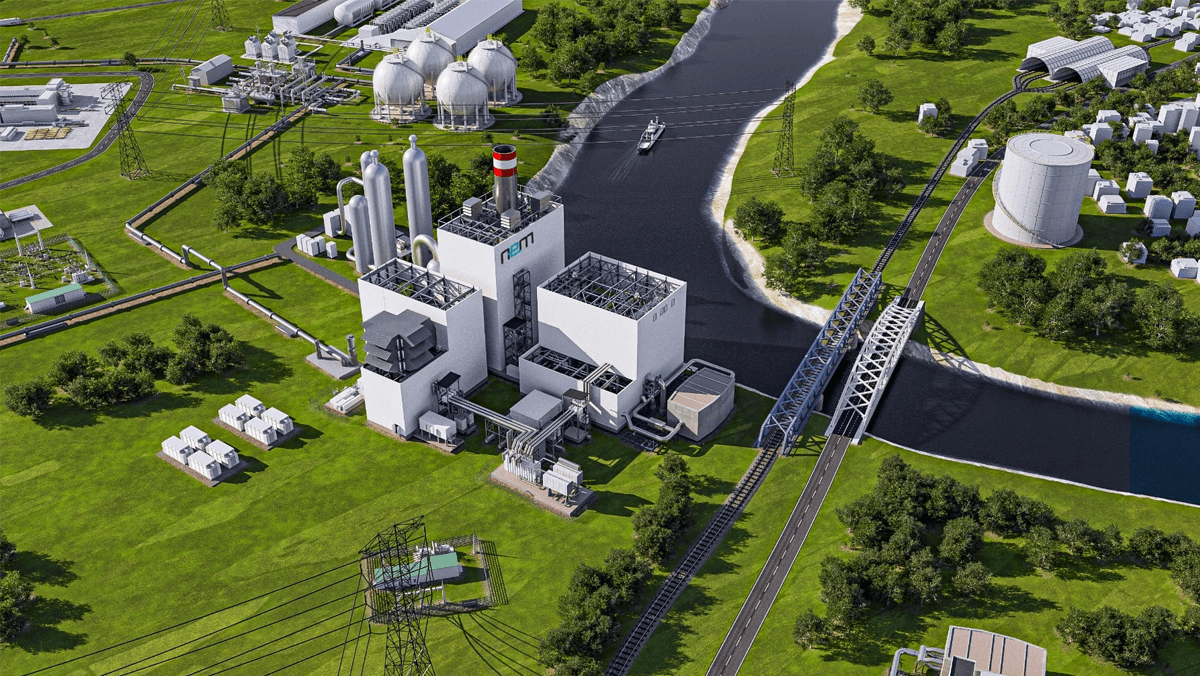

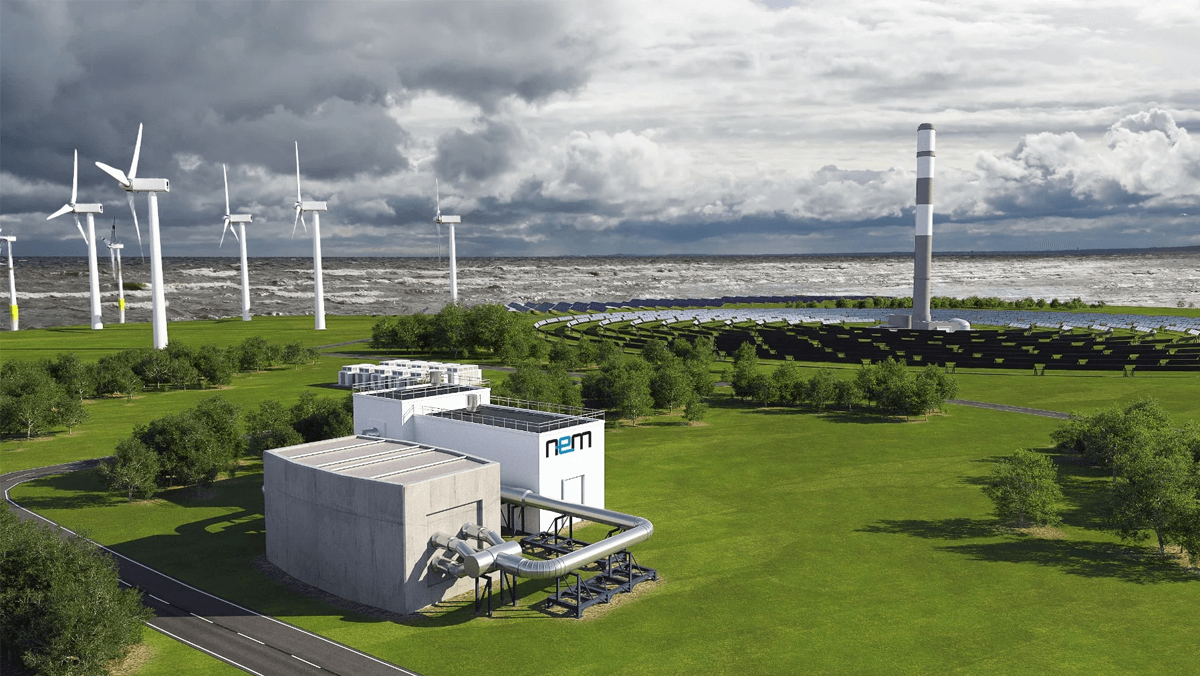

Renewables & Hydrogen

The energy transition is shaping a new energy system. Hydrogen is playing an increasingly important role, also in power generation. New natural gas-fired power generation is being prepared to make the shift to hydrogen, which is already happening today.

That means that new products need to be ready for the use of hydrogen, and in NEM, we are ready. All of the NEM products can be prepared for (future) hydrogen operations. With the use of hydrogen instead of natural gas for power generation, there are no associated CO2 emissions, or lower in the case of a hydrogen natural gas mixture. However, there are some design considerations when it comes to dealing with it as fuel. At NEM, we know these challenges, and we can support our customers in becoming ready for that future.

Heat is one of the most important elements in the energy landscape. Most of the world’s energy demand comes in the form of heat. Many industries need heat in their production processes, from cement plants to petrochemical facilities. All of those industries rely on heat supplies for their end product. At NEM, we are developing new energy solutions in the area of ‘power-to-heat‘, which literally means using electricity directly to generate heat. NEM aims to be a key supplier of electric heaters for higher temperatures in the megawatt range.

Check out our products and aftermarket services in this market:

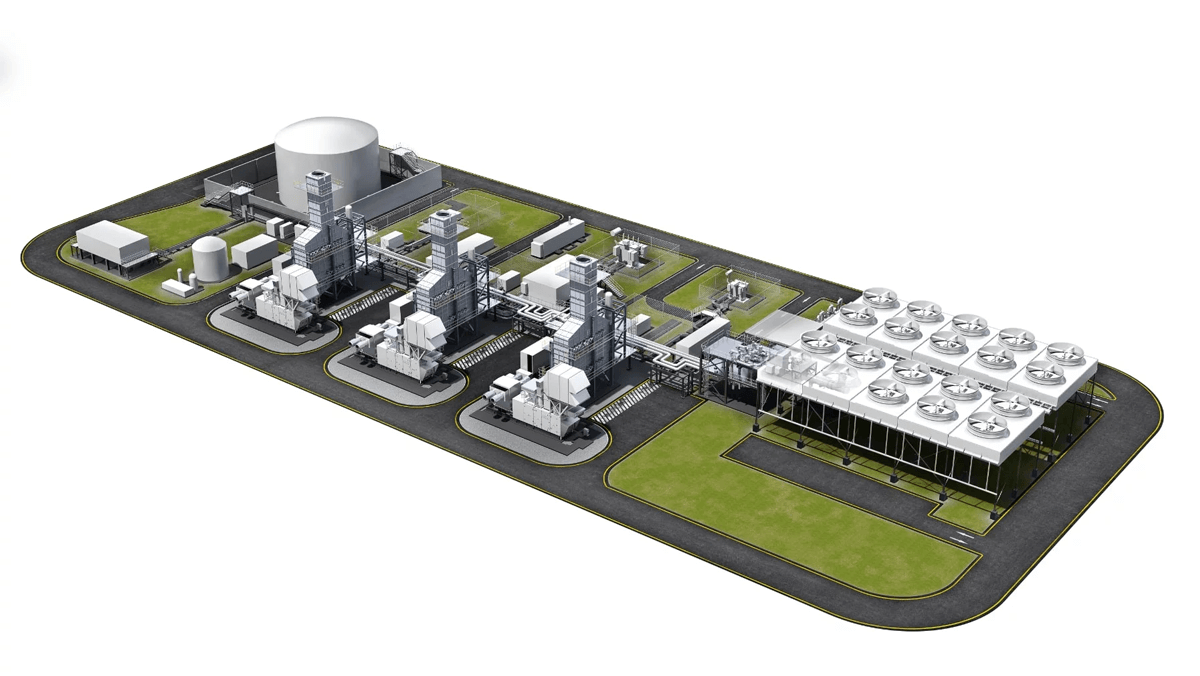

Energy Storage

Heat transfer is needed throughout the energy value chain, also in energy storage applications.

For instance, in Compressed Air Energy Storage, known as CAES, electrical energy can be stored for longer periods of time and on a gigawatt scale. CAES improves the utilization of renewable energy resources by absorbing GW-hours of energy that would otherwise be curtailed and provides grid balancing and reserve services.

The CAES solutions work with a so-called expander cycle where the exhaust heat is going through a waste heat recovery unit, one of NEM’s key products that can be used for waste heat recovery in various applications.

Thermal energy storage applications are also becoming increasingly popular. Here, the energy is stored in the form of heat. In thermal energy storage, heat transfer is key, as the electrical energy has to be converted into thermal energy and, often, also vice versa.

Thermal energy storage applications have as advantage that they can be used in cases when heat is the primary need of the customer, either as back-up or as an intermediate to balance the demand and supply of heat in the user’s process. NEM’s heat recovery products can be found in various thermal energy storage applications.

Check out our products and aftermarket services in this market:

Nuclear

Nuclear power plants use a wide variety of heat exchangers in their steam cycles, whether for power generation alone or for combined power and heat generation.

NEM is able to provide technology for a new generation of nuclear plants, including small and modular plants.

In a nuclear power plant, the steam cycle is a thermodynamic process that converts heat generated by nuclear reaction into electricity. Water is heated and turned into steam, which drives a turbine connected to a generator to produce electricity. The steam from the steam turbine is first regenerated and returned to the cycle with NEM’s Moisture Separator Reheaters (MSRs) to improve the steam quality and the overall efficiency.

As the world shifts toward cleaner energy sources, nuclear power, with its minimal carbon emissions, is increasingly recognized as a vital part of the energy transition. NEM Energy’s MSRs support this shift by optimizing nuclear power generation, making it a more sustainable and efficient option.

PowerVane technology enables efficient moisture separation: by removing moisture and reheating steam, MSRs significantly improve the thermal efficiency of nuclear power plants. This enhancement leads to increased power output and reduced operational costs, ultimately boosting the overall efficiency and reliability of nuclear power plants.

Check out our products and aftermarket services in this market:

Geothermal

As the energy sector accelerates its transition to sustainable solutions, geothermal energy is emerging as a key renewable source. In regions with high geothermal potential, supportive government policies are driving demand and accelerating the pace of this transition.

By harnessing the Earth’s internal heat, geothermal systems provide a reliable, renewable, and efficient energy source without CO₂ emissions.

As the world shifts toward cleaner energy sources, nuclear power, without carbon emissions, is increasingly recognized as a vital part of the energy transition. NEM Energy’s MSRs support this shift by optimizing nuclear power generation, making it a more sustainable and efficient option.

PowerVane technology enables efficient moisture separation: by removing moisture and reheating steam, MSRs significantly improve the thermal efficiency of nuclear power plants. This enhancement leads to increased power output and reduced operational costs, ultimately boosting the overall efficiency and reliability of nuclear power plants.

Download the Geothermal brochure.

Check out our products and aftermarket services in this market:

Offshore Power Generation

Offshore environments demand reliable, compact, and efficient power solutions to keep operations running in some of the most challenging conditions on Earth. From Floating Production Storage and Offloading units (FPSOs) and Floating Liquefied Natural Gas vessels (FLNGs) to power barges and marine propulsion systems, offshore power generation is critical for ensuring energy security and operational continuity.

Unlike onshore facilities, these offshore applications face unique constraints, including limited space, strict weight requirements, and the growing need for high efficiency with lower emissions. Advanced technologies such as Combined Cycle systems and NEM innovative Once-Through Steam Generators (OTSGs) make this possible, delivering cleaner, more sustainable solutions that maximize performance while minimizing footprint.

NEM’s patented Ultra-Light Bottoming Cycle (ULBC) technology sets a new benchmark for offshore power solutions by drastically reducing equipment weight and space requirements—without compromising performance. This breakthrough approach minimizes structural demands, simplifies platform integration, and optimizes layout efficiency, resulting in both cost and operational benefits.

Choosing NEM’s OTSG means more than just installing equipment—it means securing a highly efficient, compact, and reliable core component for your steam cycle, ensuring superior energy conversion and long-term sustainability for your offshore operations.

Key benefits of the NEM design:

- Reduced equipment count and streamlined once-through technology

- Compact design to prevent module size escalation

- Ensuring reduced fuel and water consumption on board

- Compliant with different types of applications