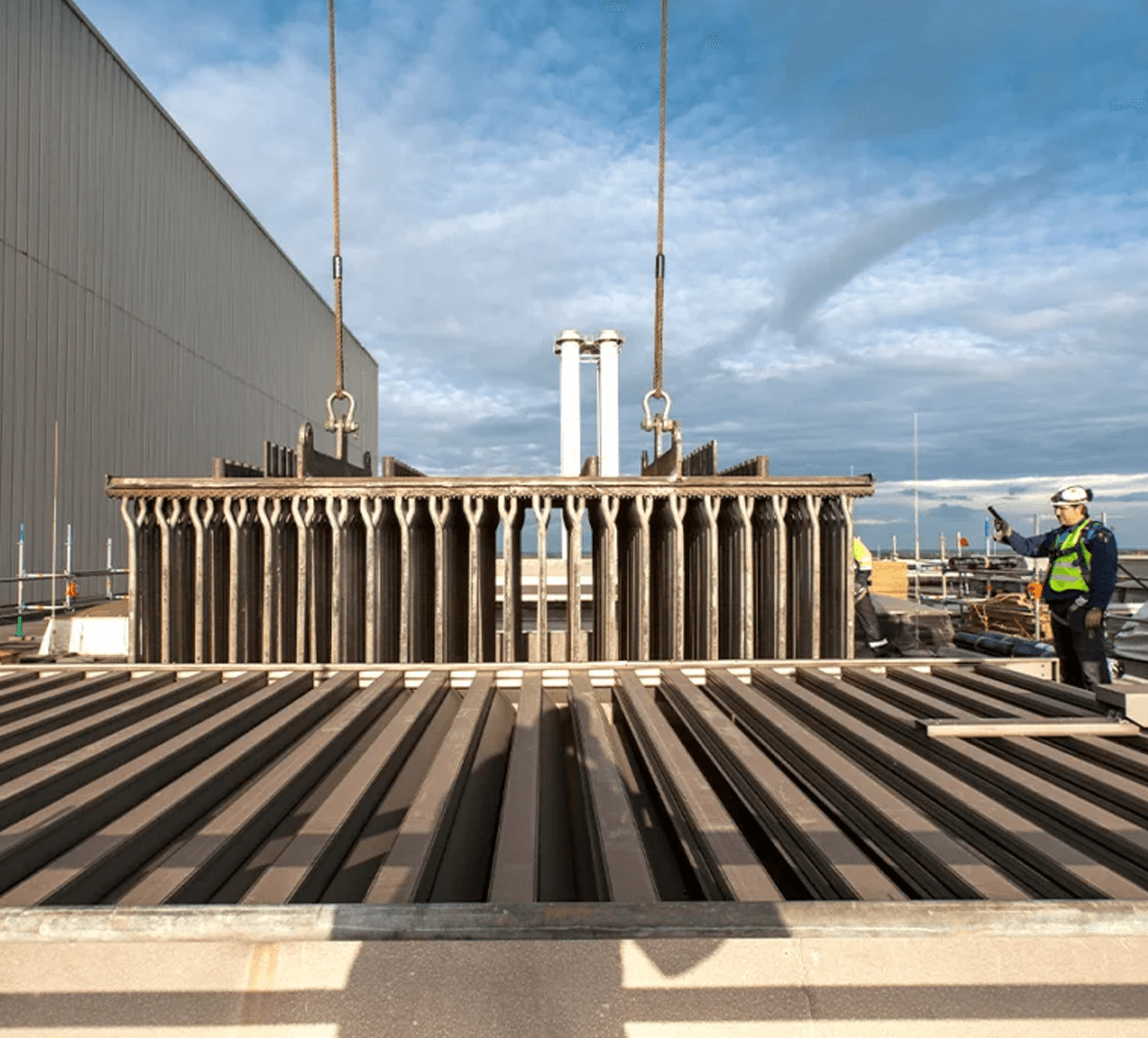

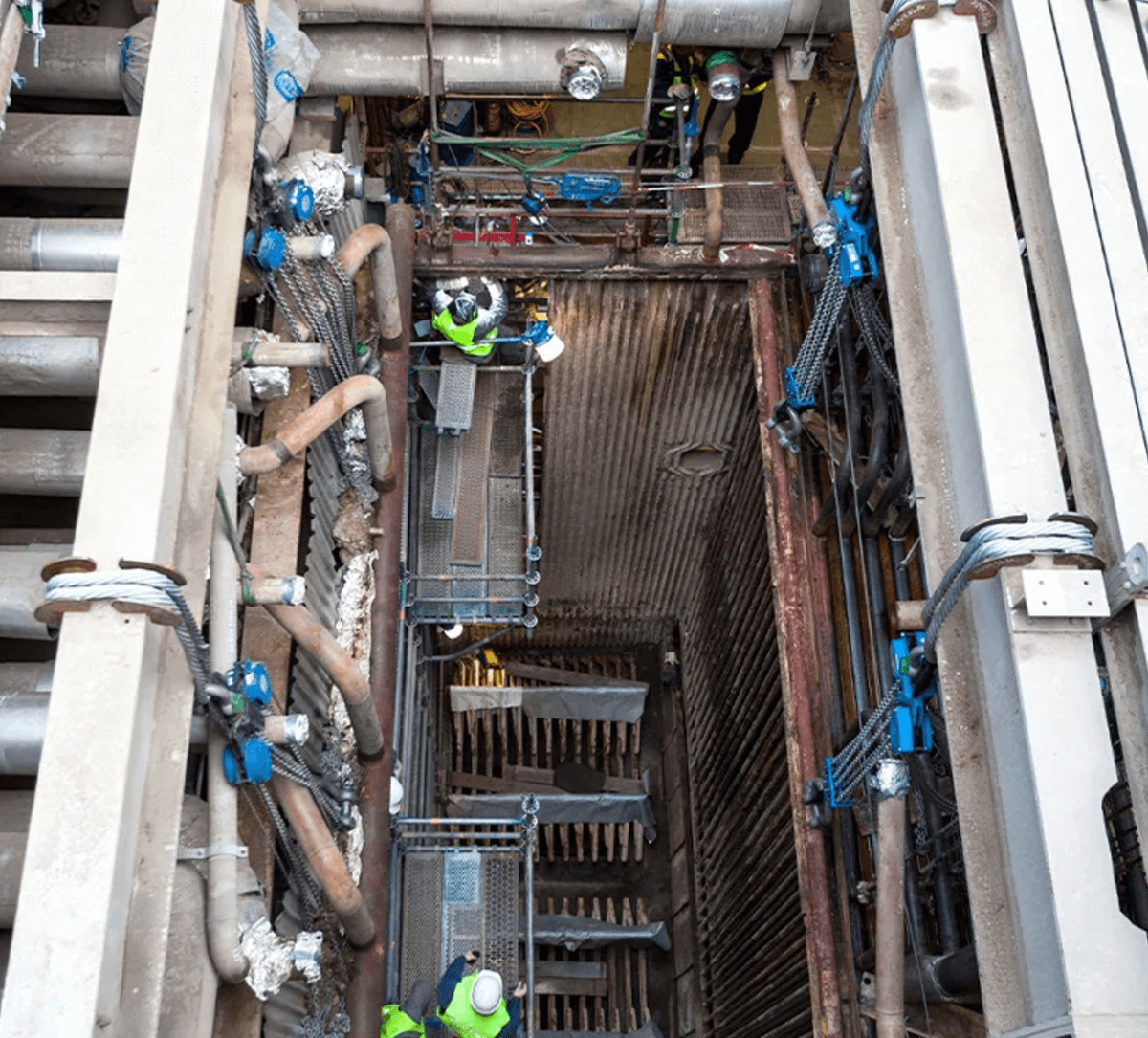

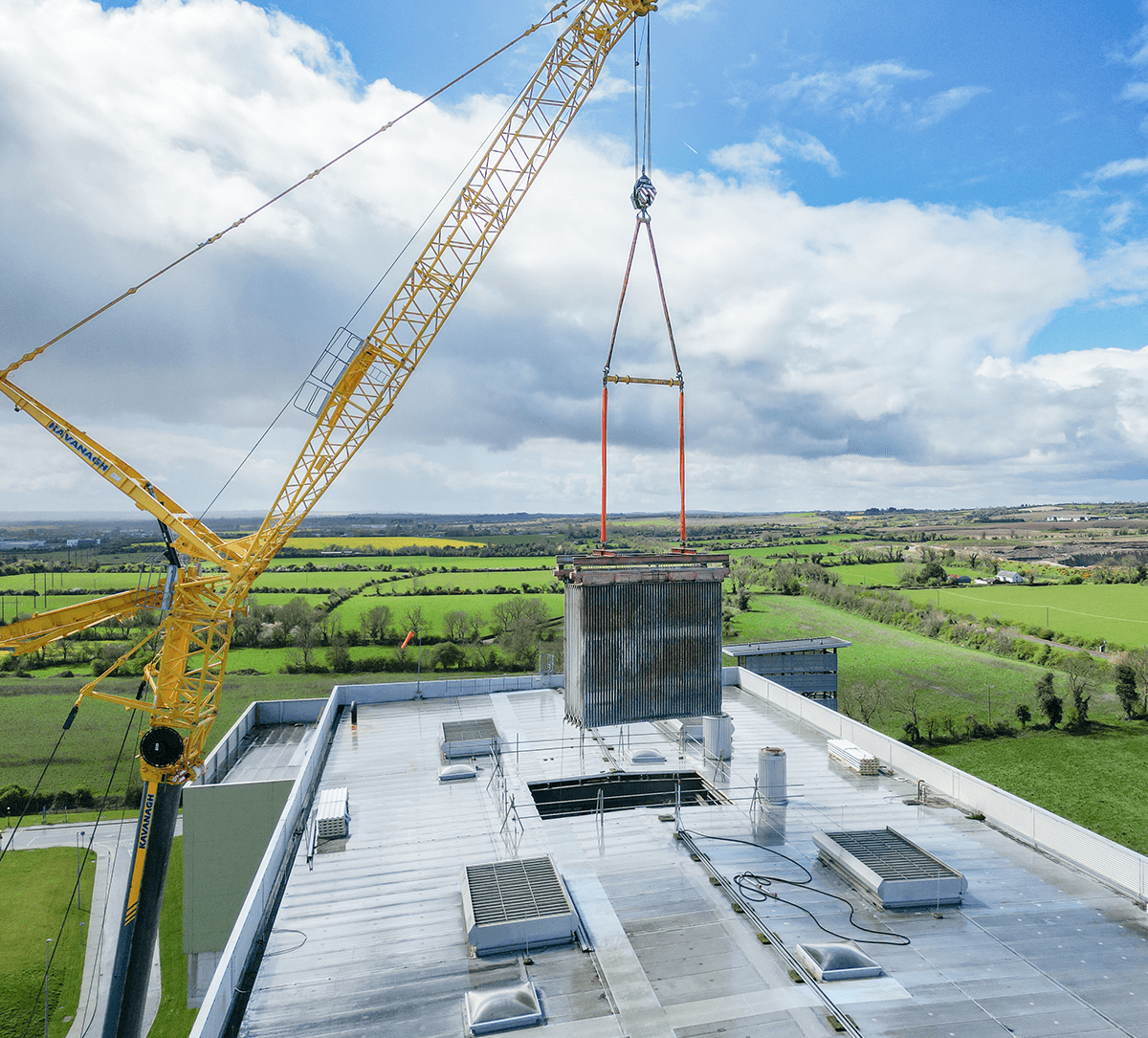

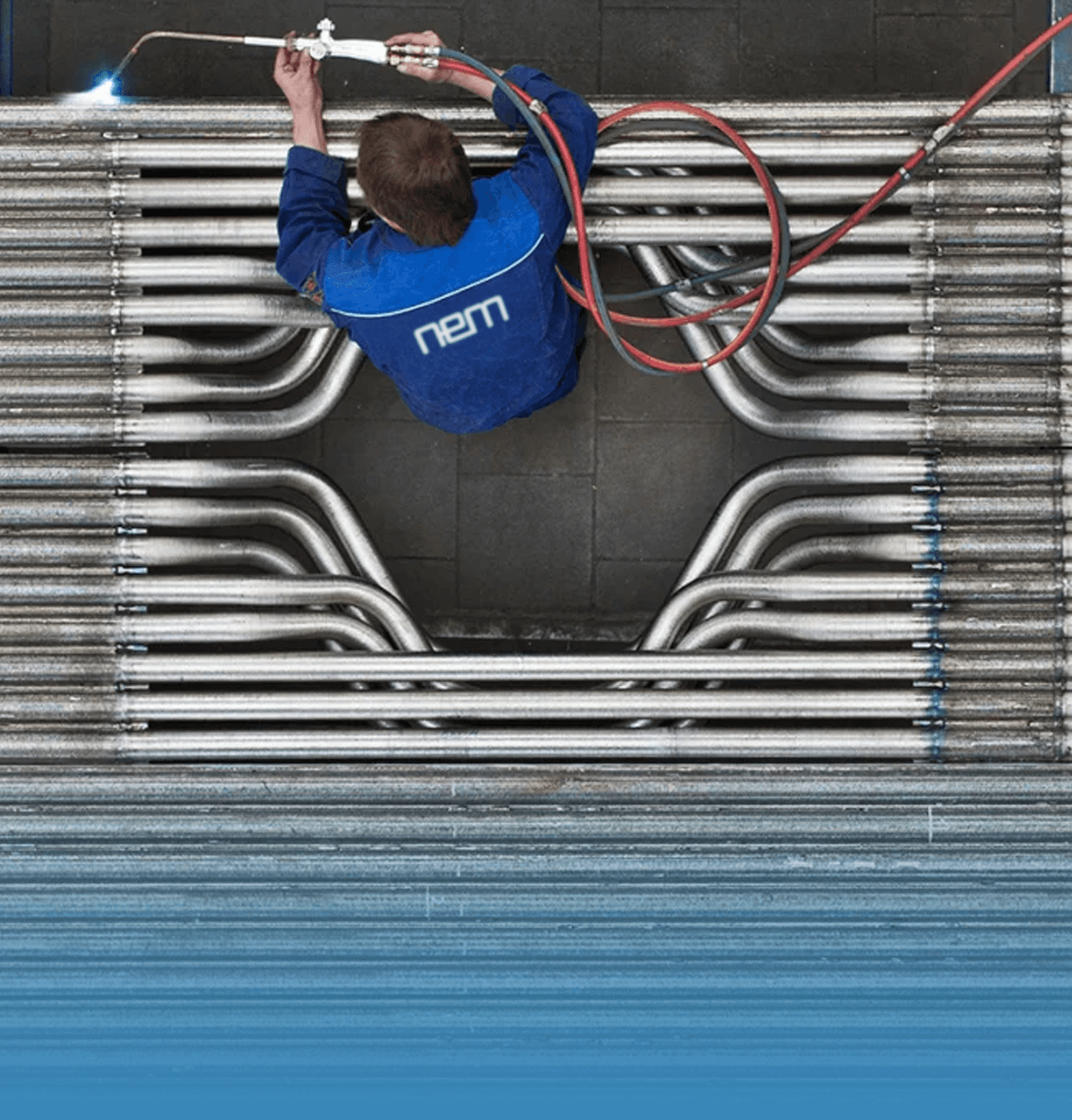

With roots dating back to 1883, NEM Balcke- Dürr’s Boiler Service proves to have extensive experience with different types of boilers. We offer services for both OEM and non-OEM boilers, including inspections, manufacturing, transport, and on-site works. The service is supported by professional Engineers for design, optimization, and assembly concepts. As a reliable partner, we support you with long-term framework agreements as well as short-term service projects with a highly qualified workforce.

Engineering & Capabilities

✓ Inspection, root cause analysis, and consultation

✓ Boiler process optimization studies in regards to performance, life time extension, and fuel replacement

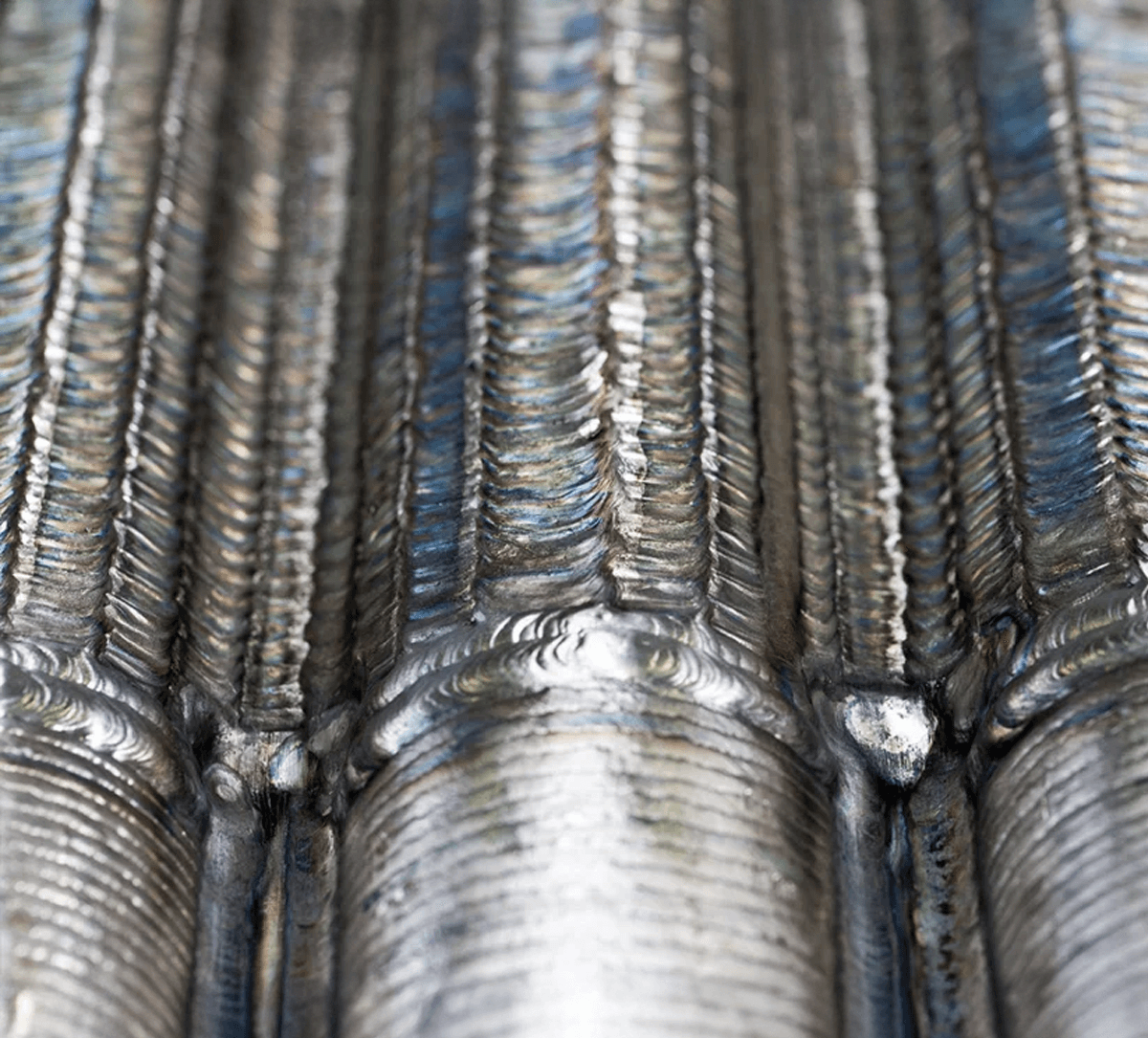

✓ Design and optimization of new heating surface and bundles

✓ Boiler overhaul, including firing technology

✓ Site works, including disassembly and installation

Torsten Schmidt

Business Unit Director Aftermarket Services

Would you like to learn more about our Aftermarket Services or discuss how we can support your operations? Feel free to reach out to the Director of our Aftermarket Services Business Unit – we’re here to help and happy to answer any questions you may have.

Send Email