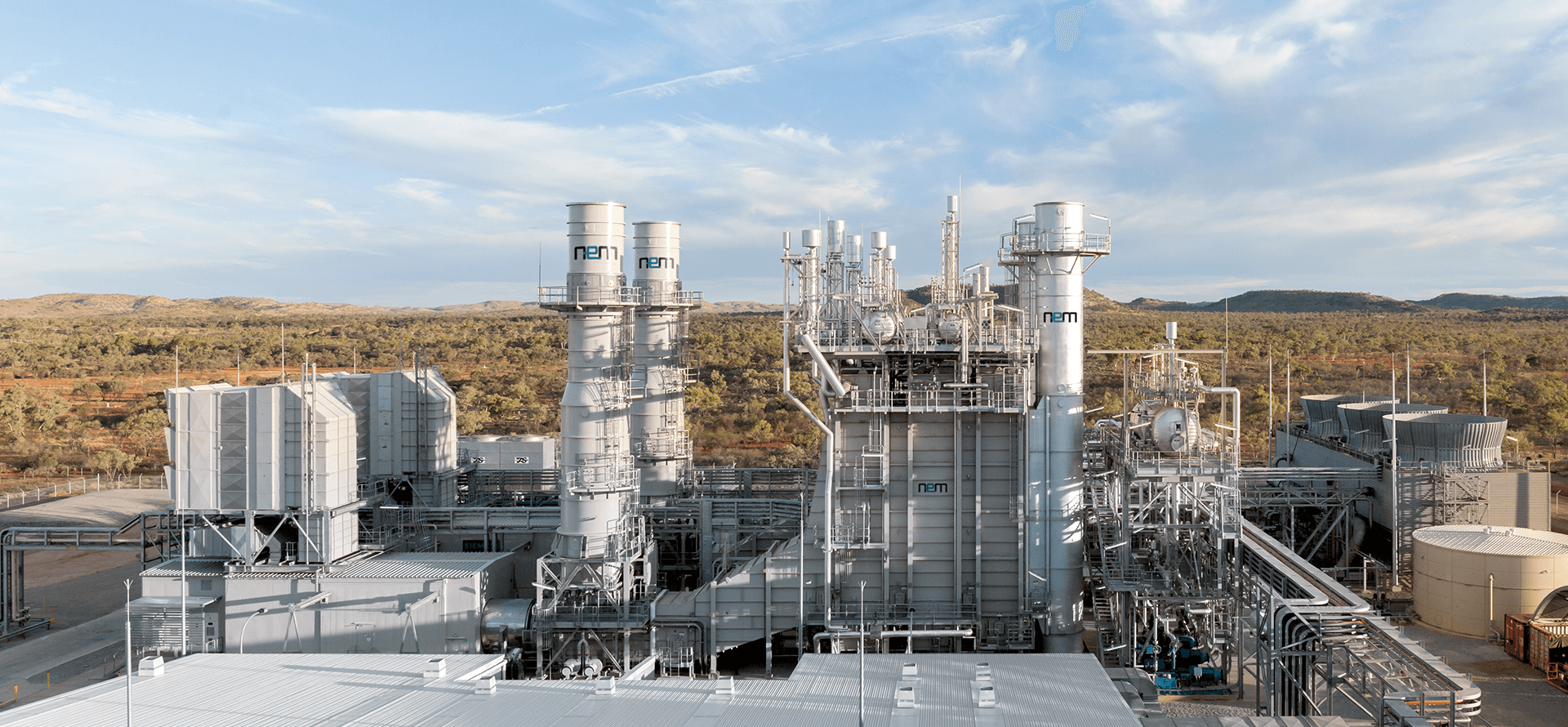

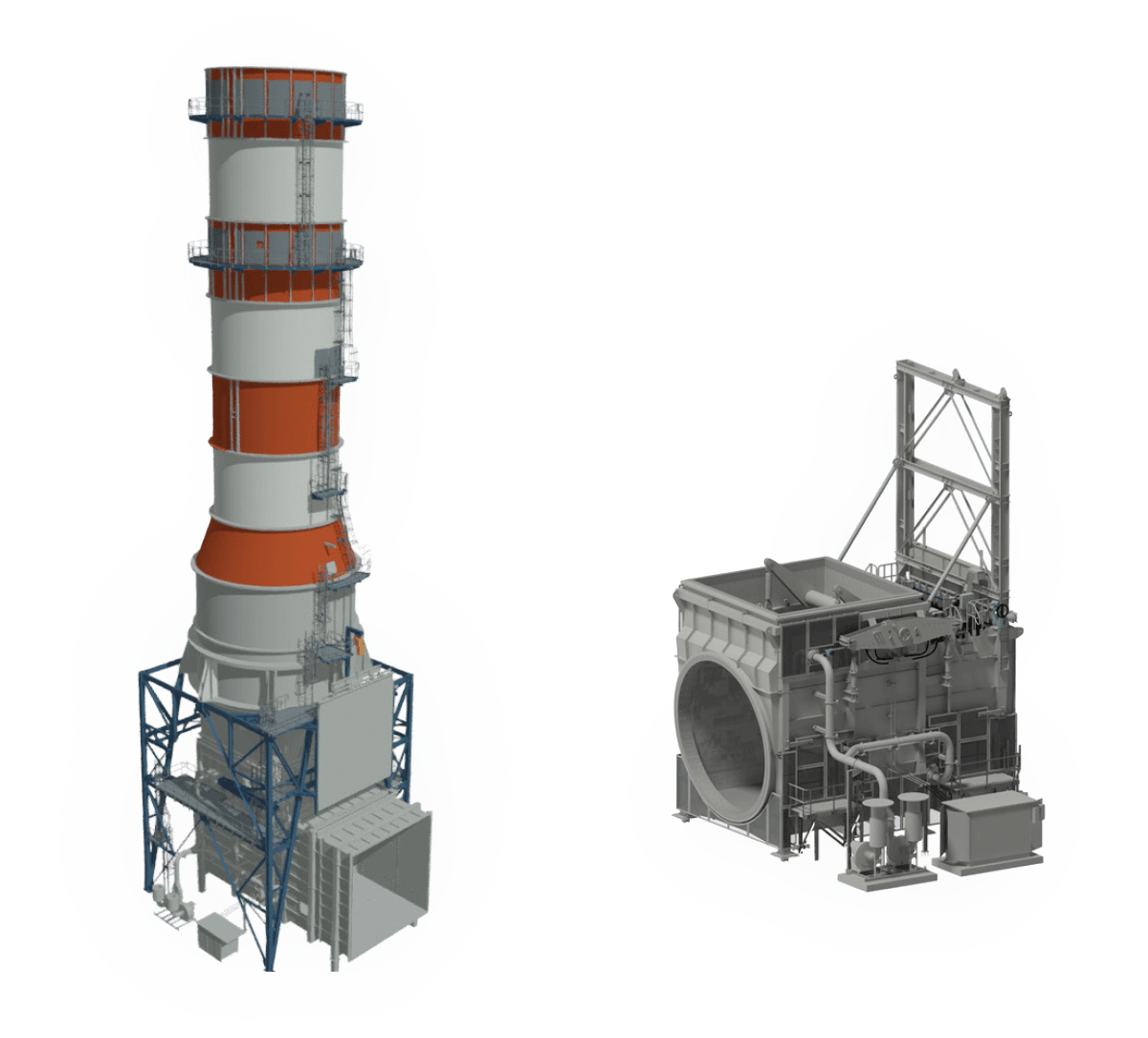

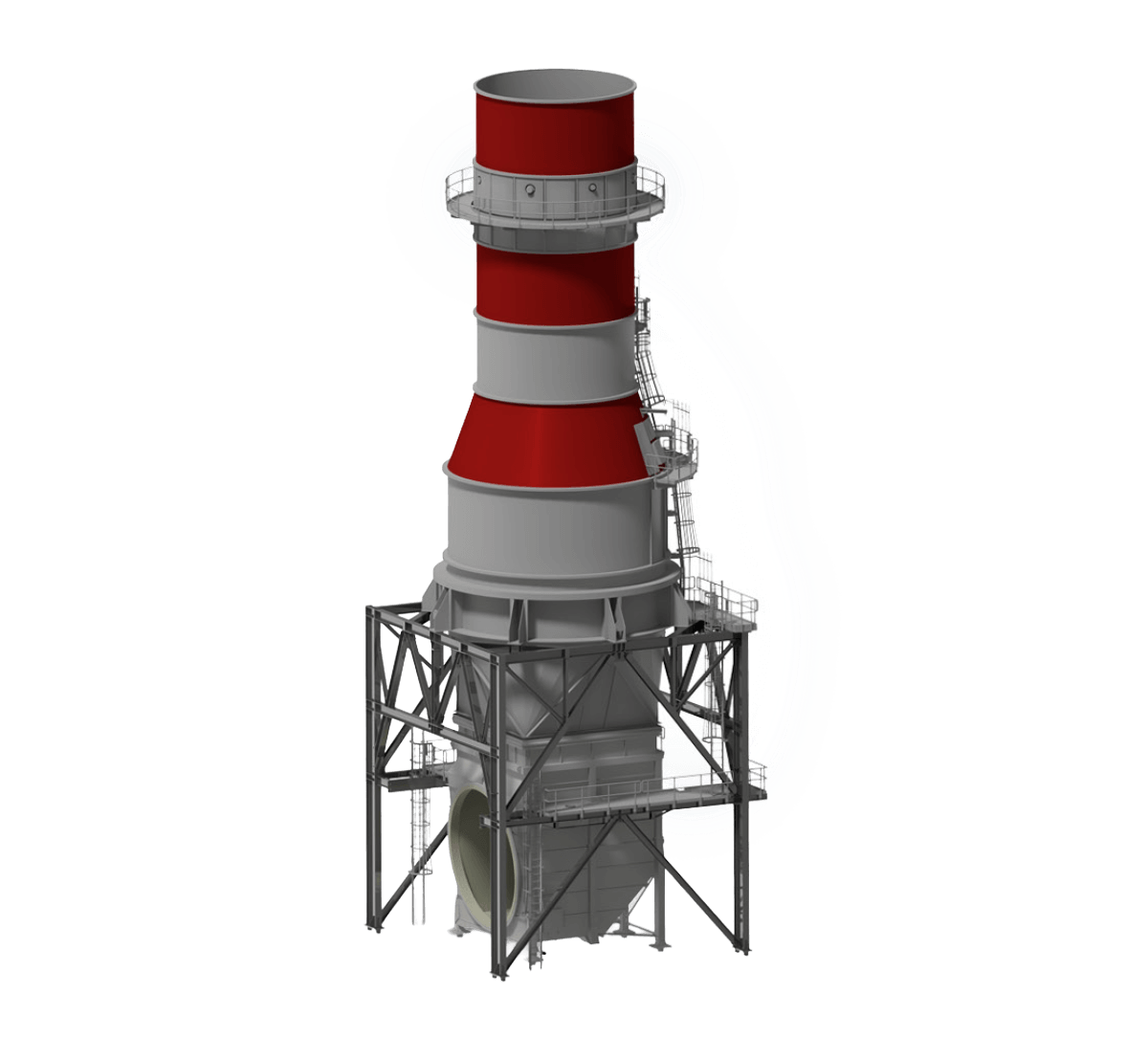

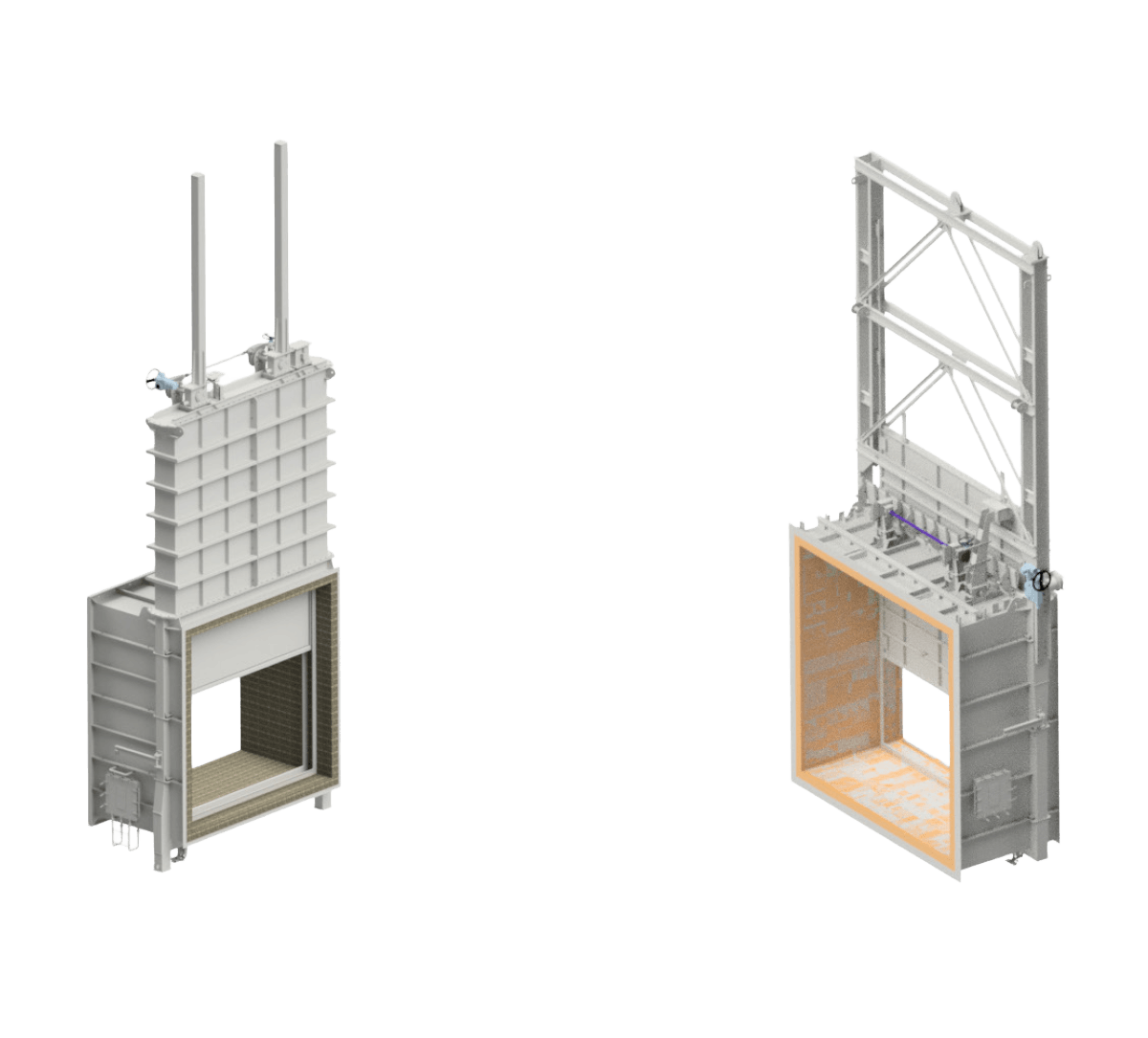

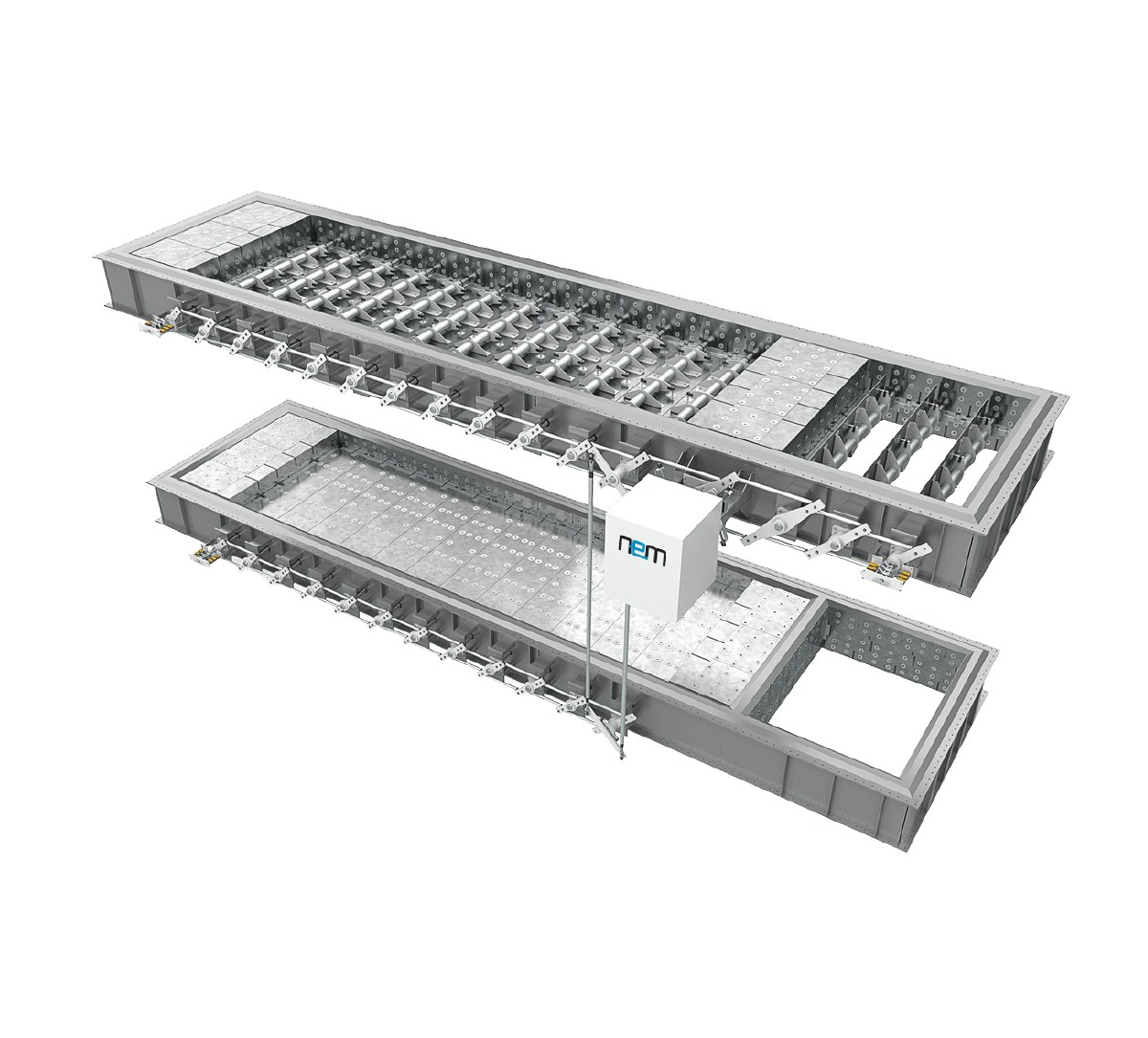

NEM is a global leader in the field of gas turbine exhaust systems requiring clever flue gas routing, modulation, and tight shut-off solutions. With our customized Exhaust & Diverter Solutions portfolio, NEM complements and supports the transition towards a decarbonized and sustainable energy environment. Our portfolio covers both new installations and custom tailored retrofit solutions for conversion projects, for conversion projects, downstream any type of gas turbine OEM.

Core Competences

Our core competencies are engineering, including basic and detailed design of individual tailored solutions, structural engineering supported by state-of-the-art methods like 3D-modelling, lifetime analysis, CFD-, and FE-analysis, and project execution and manufacturing. Short delivery times and challenging cost targets are met by a high degree of standardization and through cooperation with experienced, long-term fabrication partners around the globe. On-time deliverables, workmanship, and quality are ensured by our own internal fabrication supervision, stringent quality assurance procedures, functional shop tests at every phase of the process up to packing inspections, and logistic services. All of our processes – from proposal stage to delivery and beyond – are executed based on current ISO9001, ISO14001, and ISO45001 standards.

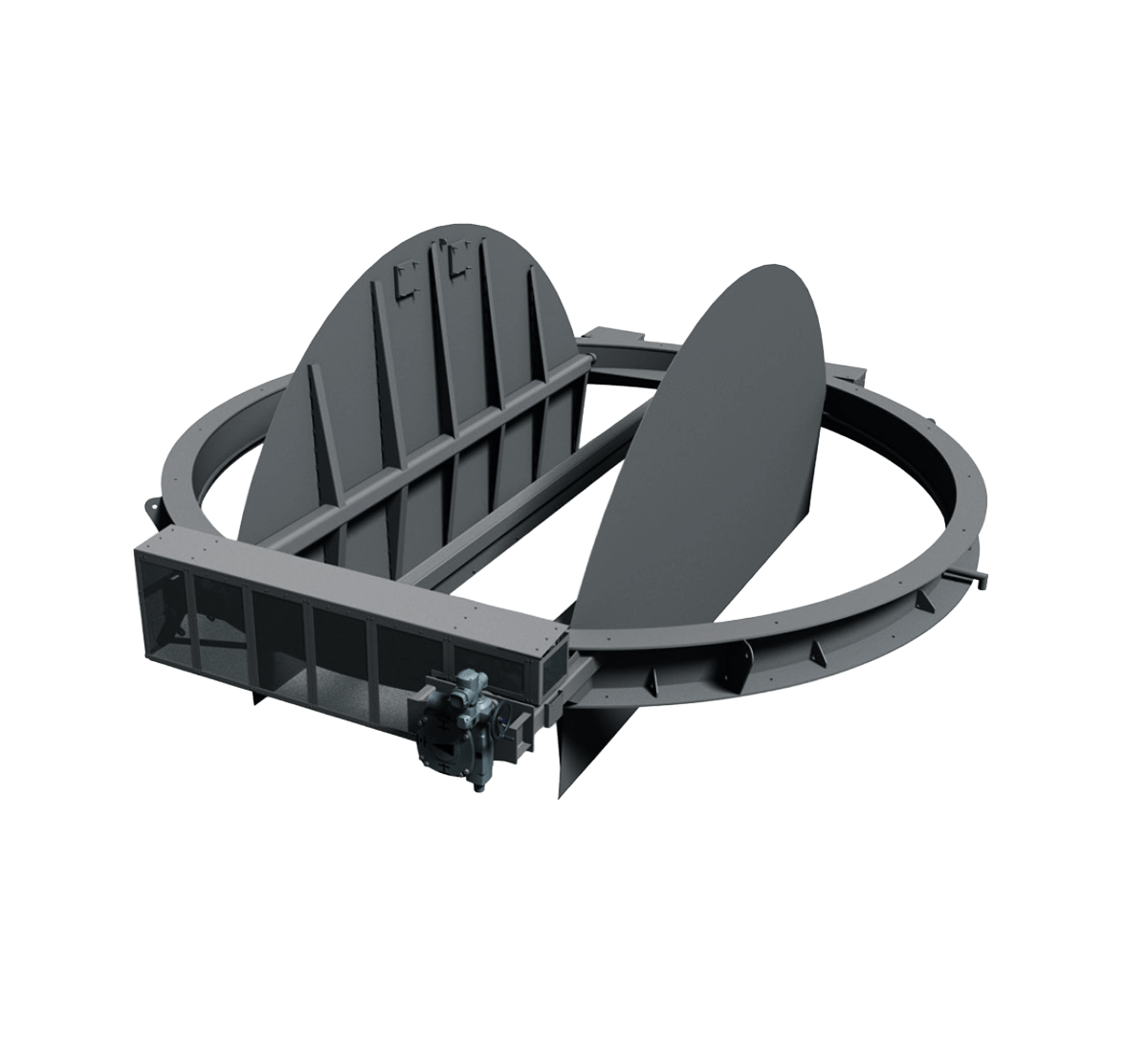

Exhaust Diverters & Dampers Project

Henry Hoiting

VP Strategy & Sales

Looking for more information about our Exhaust & Diverter Solutions or curious how we can support your installation? Feel free to reach out – we’re happy to discuss your needs and provide the right support.

Send Email