Solutions in Heat Transfer Technology

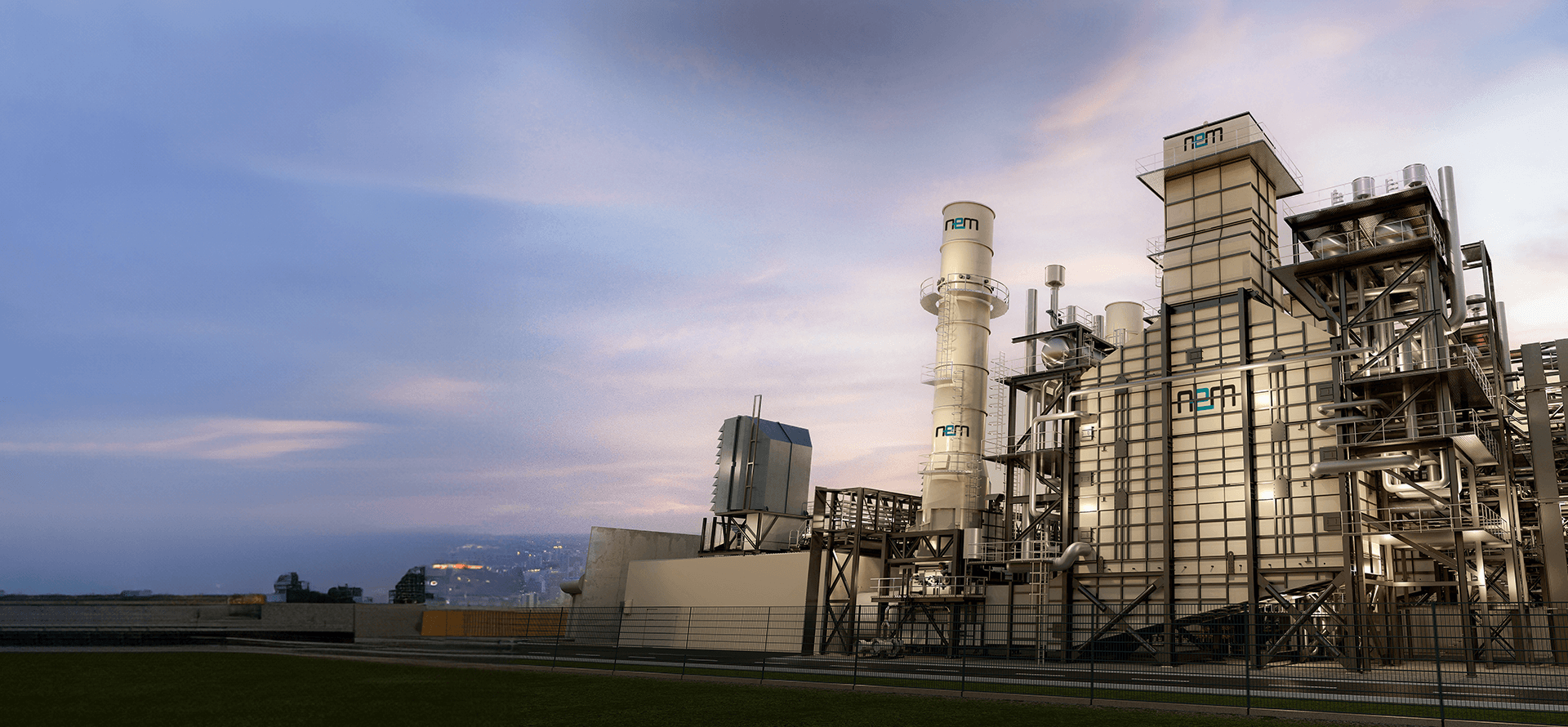

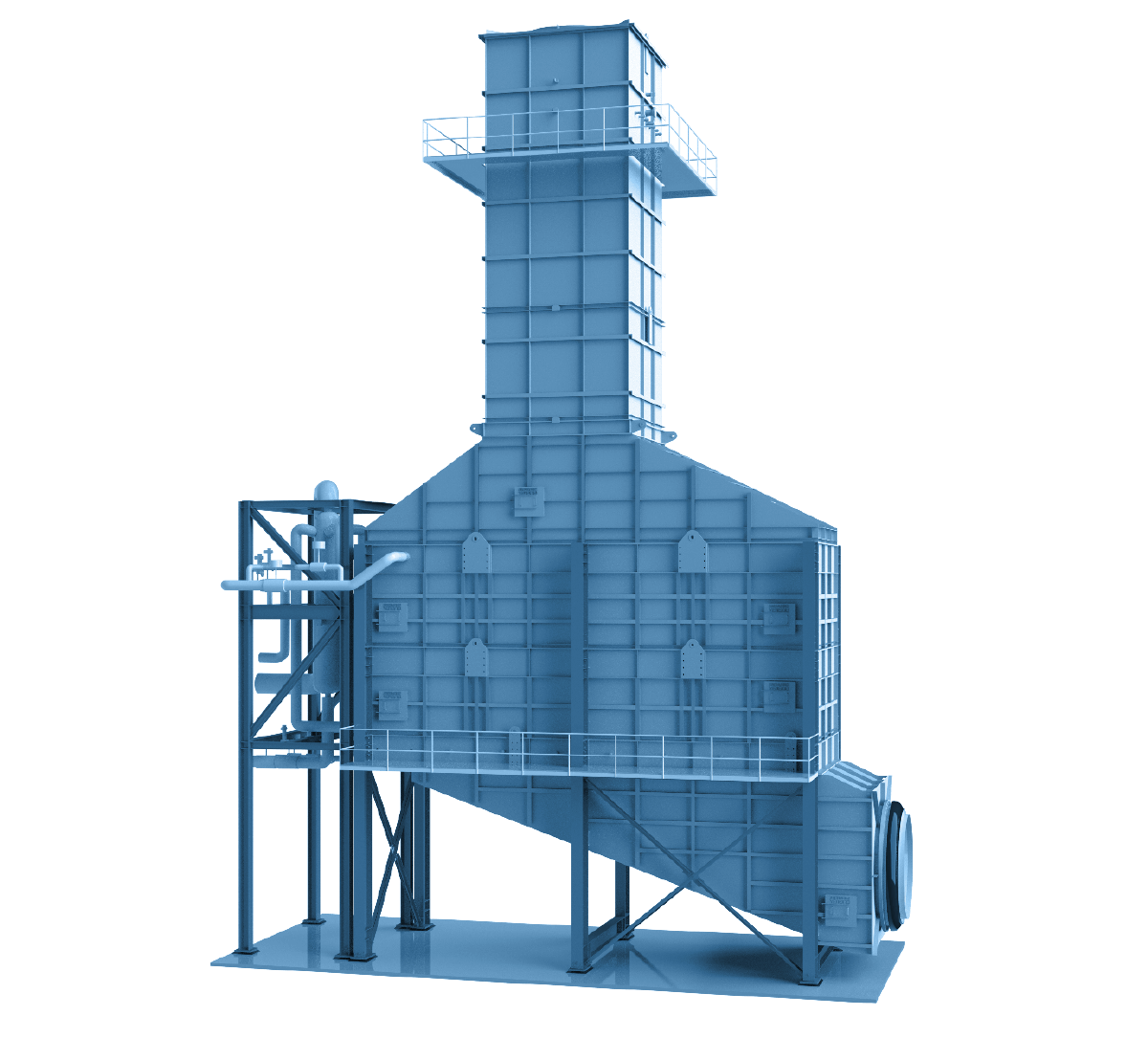

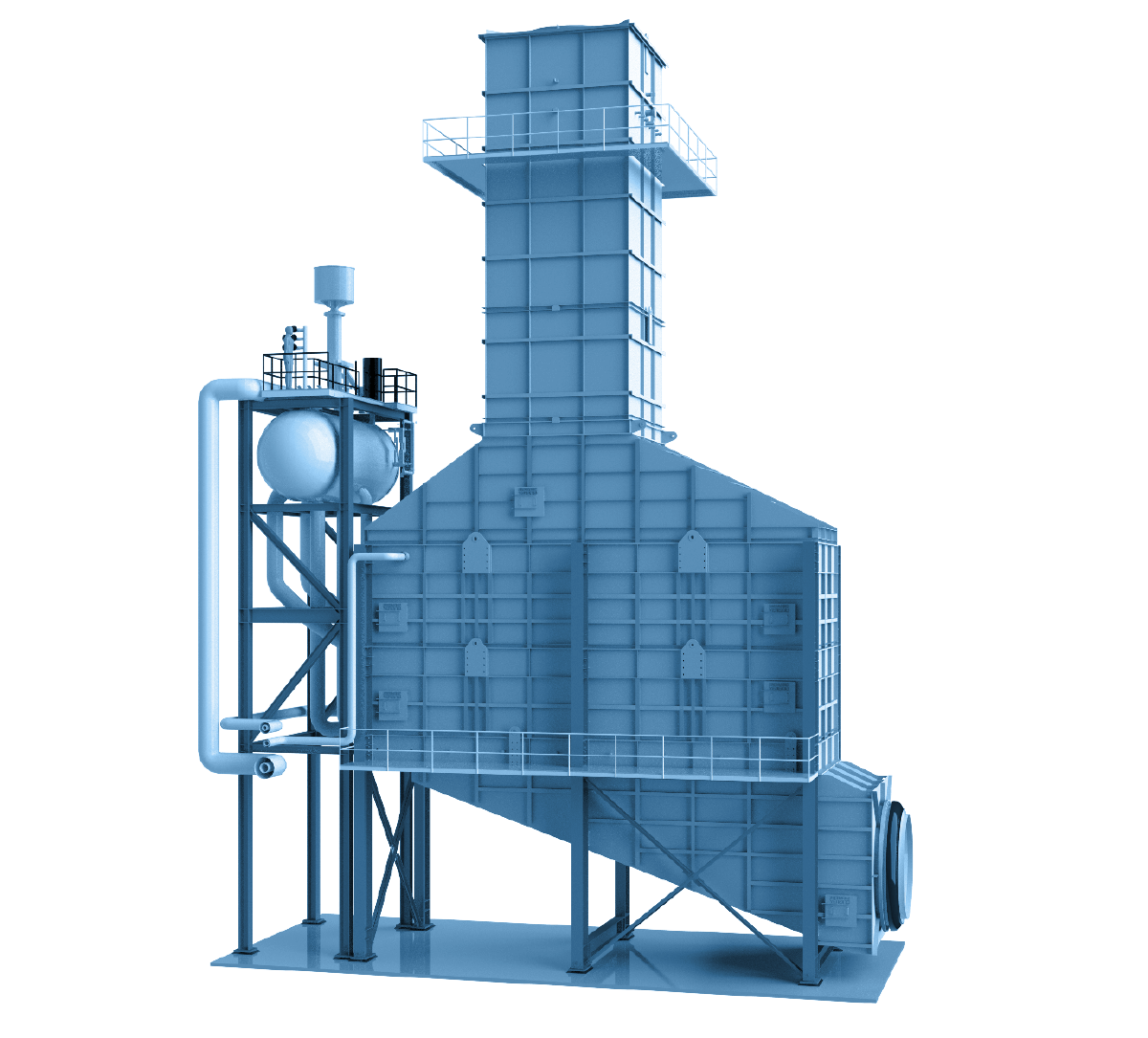

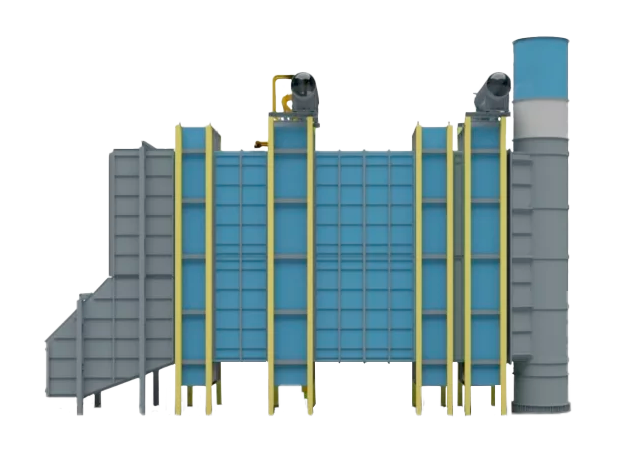

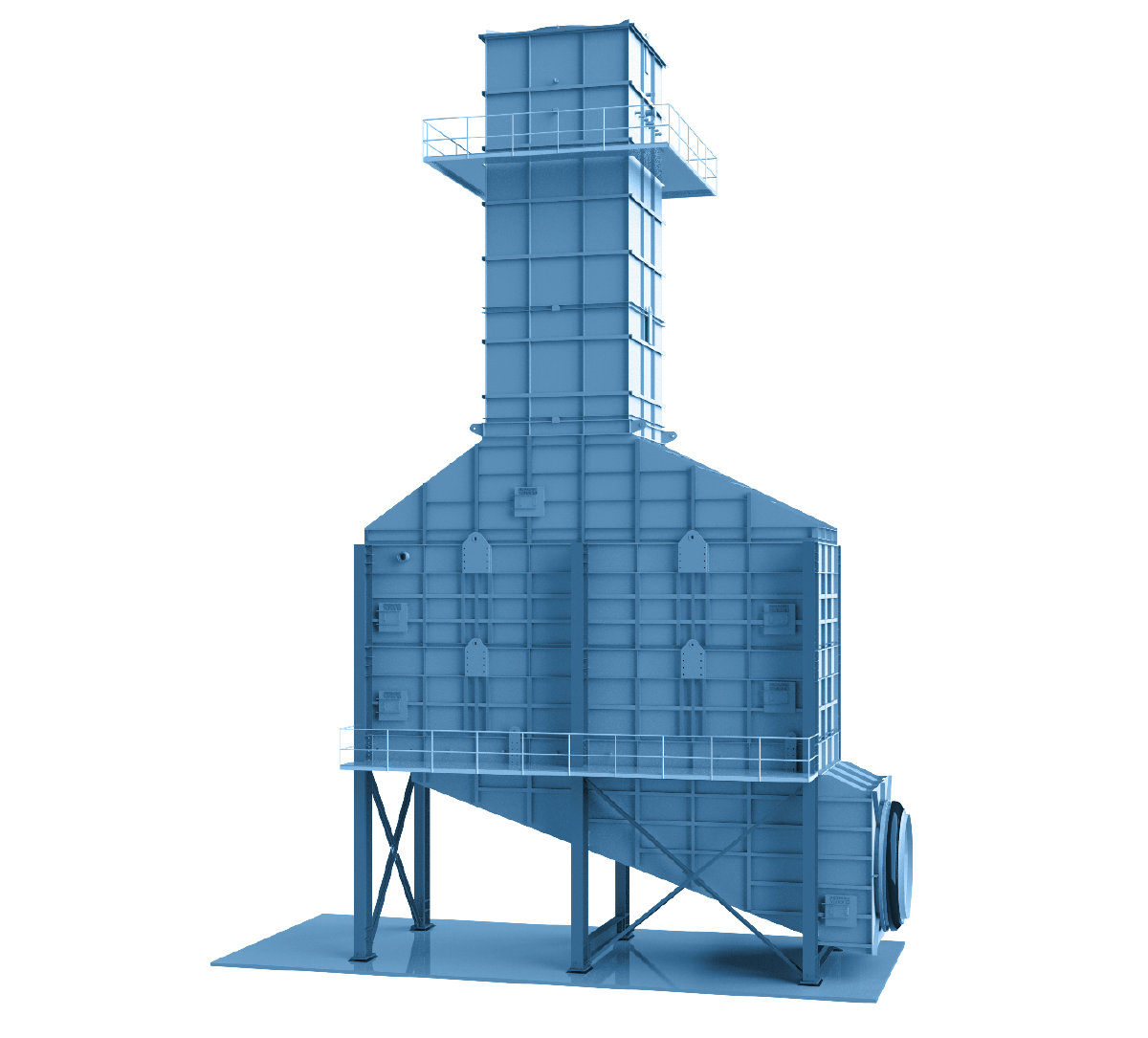

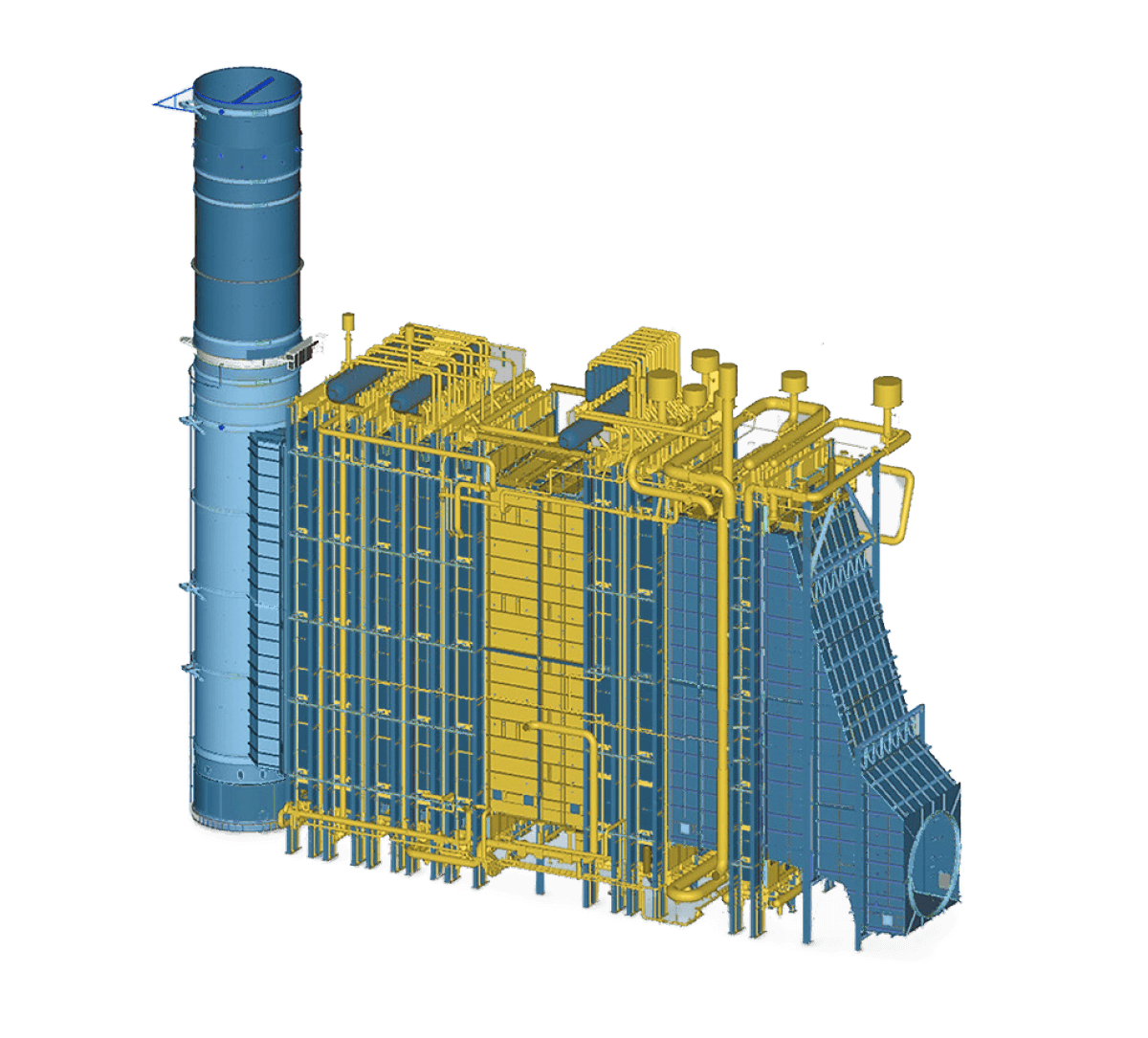

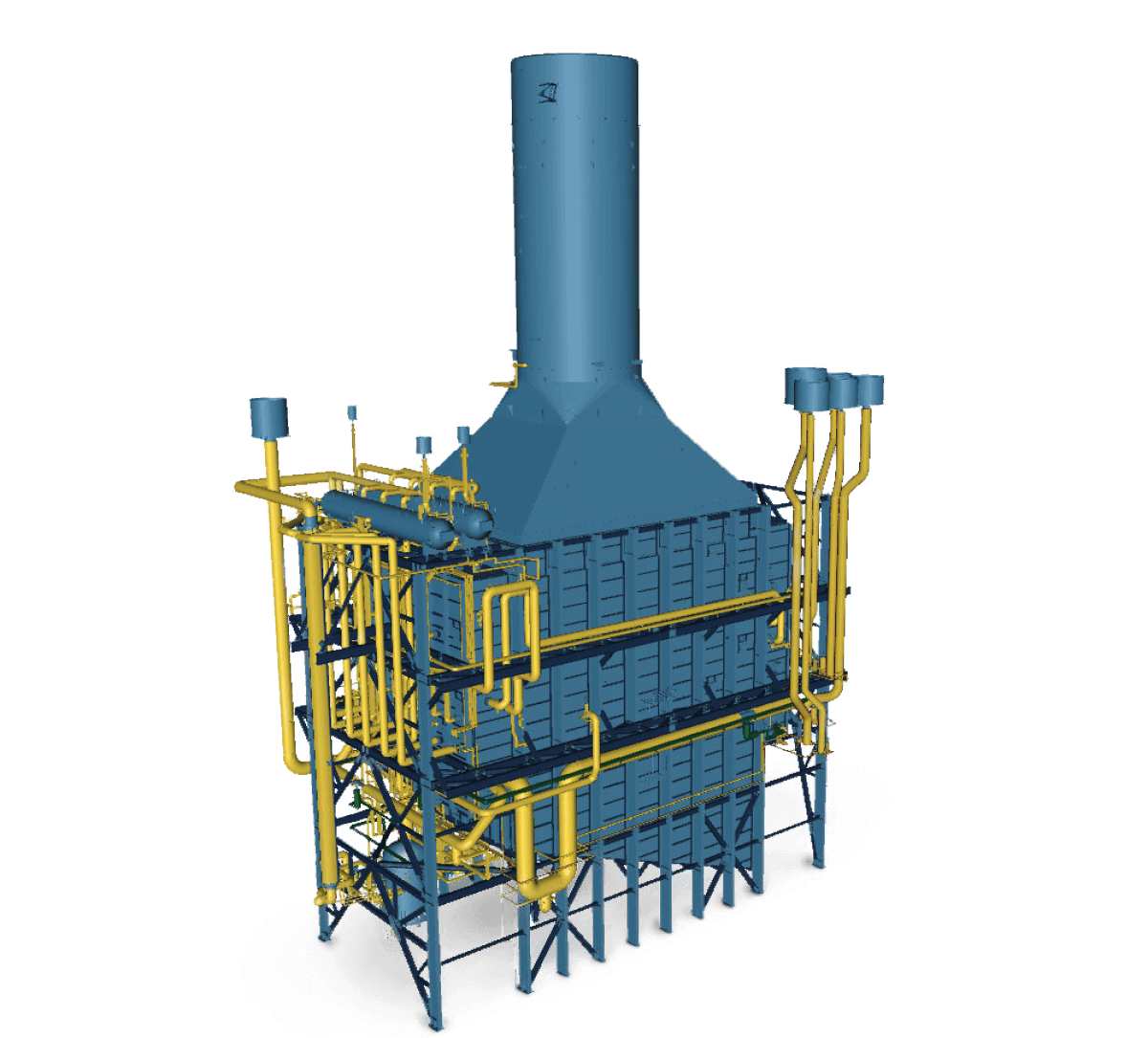

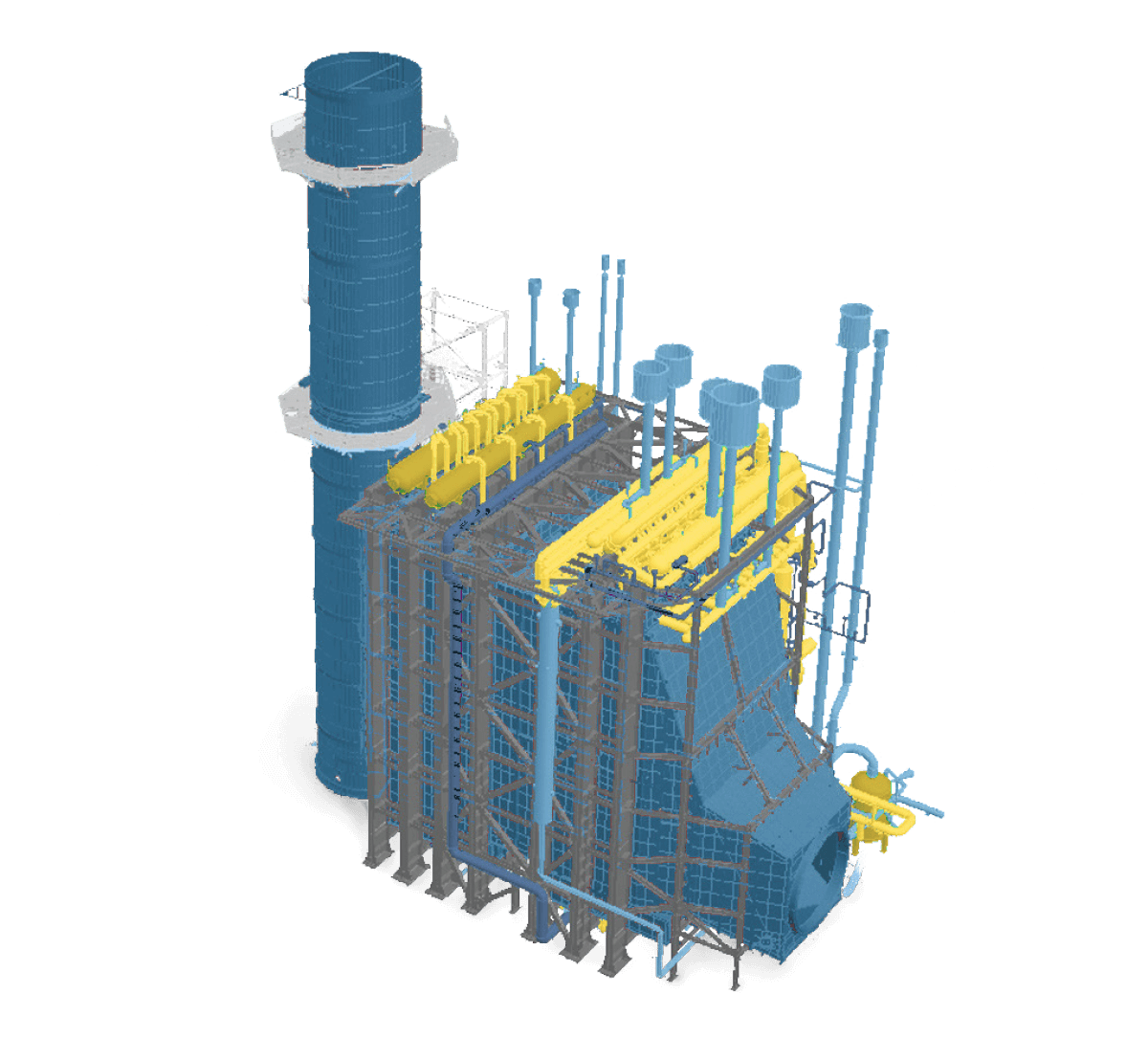

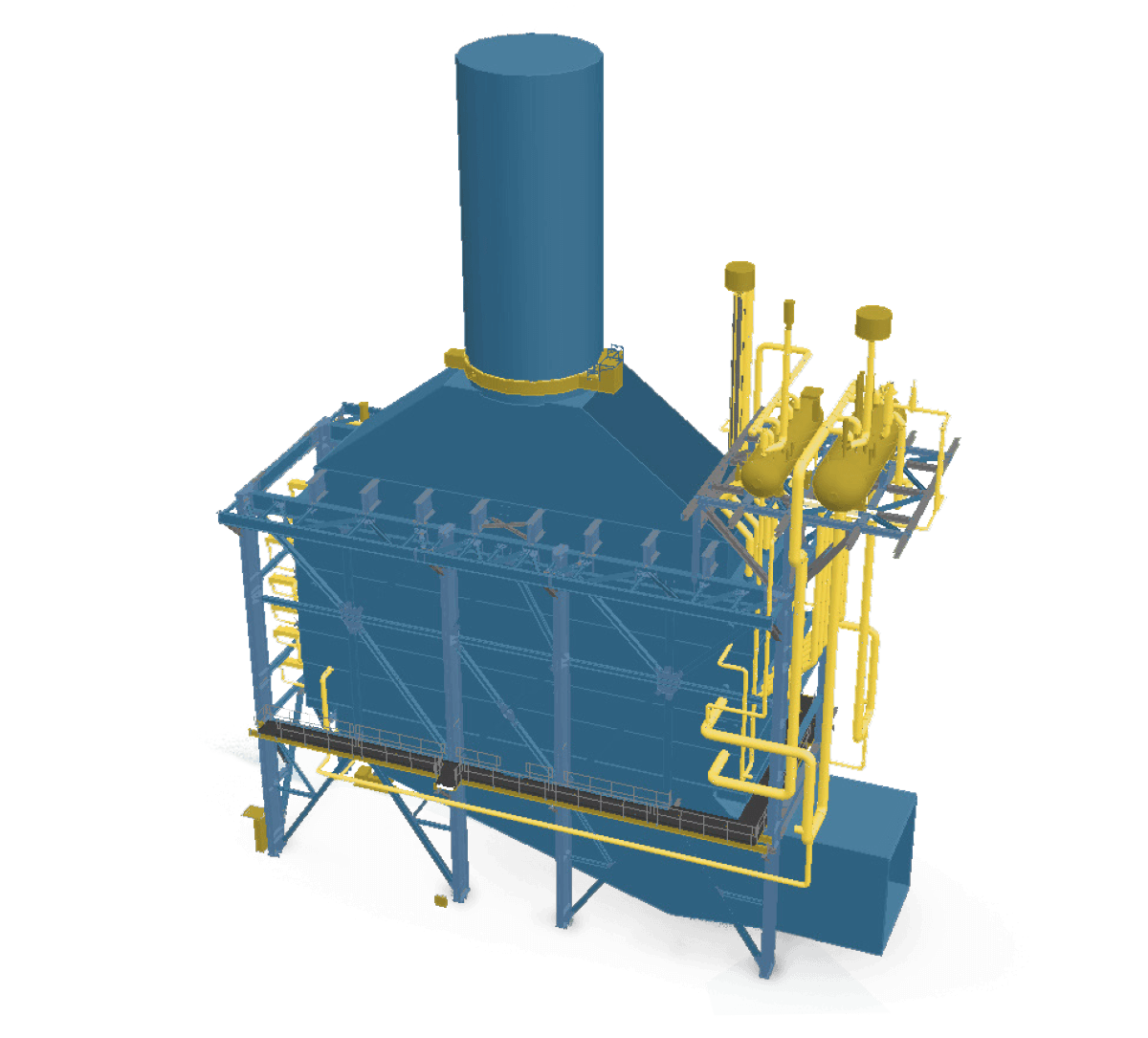

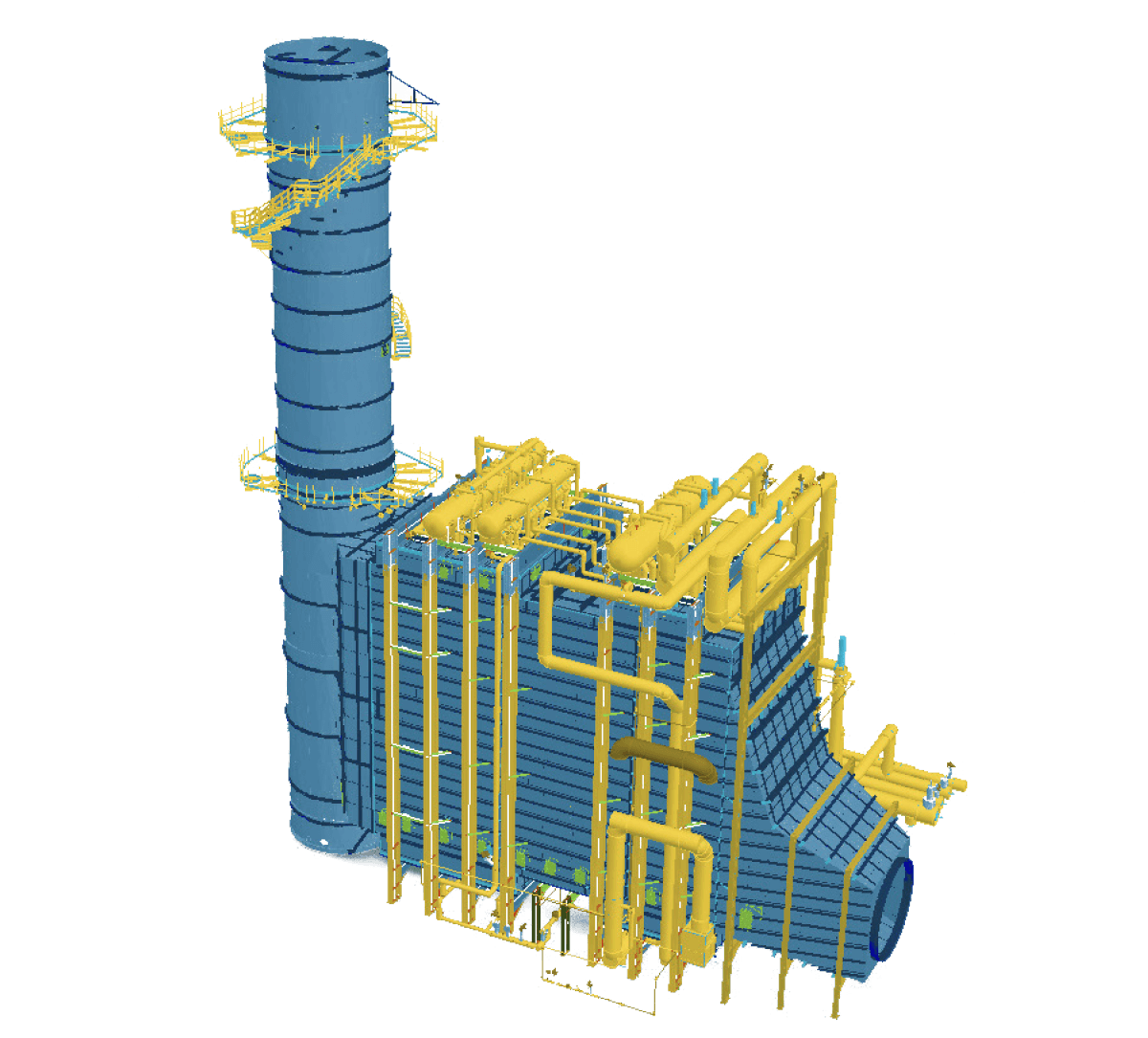

NEM Energy Group is a leading OEM of Heat Recovery Steam Generators (HRSGs) and Waste Heat Recovery Units (WHRUs). With nearly a century of experience, NEM has supplied around 1,000 units worldwide, enough to power 200 million households. Headquartered in Zoeterwoude, Netherlands, NEM serves various industries, including power generation and energy storage. Specializing in heat transfer from waste heat, NEM focuses on gas turbine exhaust as a major source. We provide HRSGs for steam and WHRUs for non-steam applications across all markets.

Download the Heat Recovery Solutions brochure.

Download the Waste Heat Recovery brochure.